With growing awareness of environmental protection, a wide variety of biodegradable and compostable plastic bags have appeared on the market. Are you curious about these? What are biodegradable plastic bags? How are they made? What are their environmental impacts?

As a professional biodegradable and compostable bag manufacturer in China, we’ve delved into what biodegradable plastic bags are, their advantages and disadvantages, the differences between compostable bags, how they’re manufactured, and how long they take to decompose. We hope this helps.

What Are Biodegradable Plastic Bags

Biodegradable plastic bags are capable of being broken down by bacteria or other organisms into carbon dioxide, water, and biomass. They degrade under natural conditions, and there’s no specific degradation timeframe. This process can occur in the presence or absence of oxygen, though it takes less time in the presence of oxygen.

How Biodegradable Plastics Work

By microbial action, they degrade faster than traditional plastics. This degradation is influenced by factors such as temperature, humidity, oxygen, and microorganisms. Some formulations rely on additives that promote the breakdown of polymer chains, making them more accessible to bacteria and other organisms. The speed and completeness of degradation depend on the specific material composition and the environmental conditions of the soil or compost.

Types of Biodegradable Plastic Bags

Bio-based Plastic Bags

Plastic bags made from renewable biomass (such as plant sugars, starches, cellulose, and vegetable oils).

They do not rely on fossil fuels like petroleum as raw materials. They typically use bioresources such as corn, sugarcane, straw, and sawdust, converted into plastic through chemical or biological processes.

Bio-based plastics are not necessarily biodegradable; their degradation depends primarily on their molecular structure, not the raw materials themselves.

Plastic Bags with Petrochemical Additives

Plastic bags containing petrochemical additives are made from traditional petrochemical raw materials (such as polyethylene (PE) and polypropylene (PP) derived from petroleum and natural gas), which are inherently non-biodegradable.

To improve degradation, “degradation additives” (such as oxidative degraders, creating OXO plastics) are added to cause the plastic to crack or decompose under certain conditions (pseudo-degradation). These plastic bags are still based on petrochemical raw materials, but contain chemical additives to accelerate the decomposition process.

These additive-containing plastic bags often produce microplastics upon decomposition, which still pollute the environment and are not truly biodegradable.

- France: A circular economy and anti-waste law sets a goal of ending the sale of single-use plastic packaging by 2040. France has developed a “3R” strategy (reduce, reuse, and recycle single-use plastic packaging) and a five-year “3R” decree.(https://www.ecologie.gouv.fr/politiques-publiques/fin-sacs-plastique)

- China: Shanghai’s strictest plastic restriction order will officially take effect on September 1, 2024. Disposable tableware must be replaced with recyclable and easily recyclable products. Violators may face fines of up to 100,000 yuan or even business closure. Penalties are based on Article 32 of the Shanghai Municipal Environmental Protection Regulations and Article 106 of the National Solid Waste Law.(https://baijiahao.baidu.com/s?id=1839848528010733444&wfr=spider&for=pc)

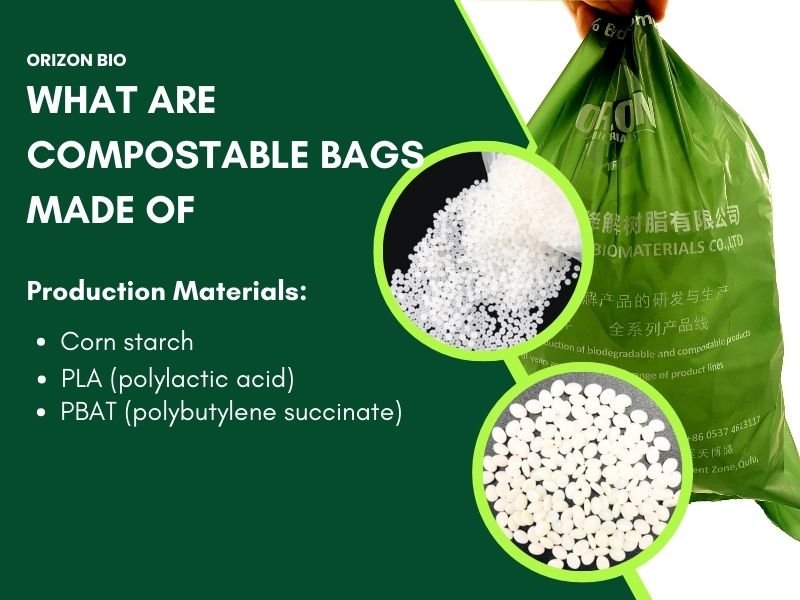

What Are Biodegradable Plastic Bags Made Of

Biodegradable plastic bags are made from a variety of materials, including starch-based biodegradable polymers derived from corn, potatoes, or cassava. Other materials include bioplastics, which are plastics made from renewable resources. For example, polylactic acid (PLA), a biopolymer derived from plant starch, is commonly used in food packaging. These materials are designed to degrade naturally over time, reducing the impact of plastic waste on the environment.

Biodegradable vs. Compostable Bags

| Aspect | Biodegradable Plastic Bags | Compostable Bags | Relationship |

|---|---|---|---|

| Material Basis | Plastics (e.g., PBAT, PLA, PBS, PHA, or blends) | Plastics (e.g., PLA, PBAT, PHA, PBS, or blends) | Same material basis |

| Core Definition | Eventually broken down by microbes | Fully breaks down into safe compost under specific conditions | Stricter definition |

| Degradation Environment | Natural environments (soil, water), landfills, or unspecified | Industrial/home composting systems (controlled temp/moisture/microbes) | Specific environment required |

| Time Requirement | No fixed timeline (months to decades) | Certified timeline (e.g., ≤6 months in industrial composting) | Time-bound decomposition |

| Safety & Residues | May leave microplastics or toxic residues | Zero toxic residues; passes ecotoxicity tests; no microplastics | Guaranteed safety |

| Key Standards | None mandated | EN 13432, ASTM D6400, AS 5810 (certification required) | Third-party verification essential |

| Certification | Rarely certified; vague claims | Mandatory labels: • Seedling (🇪🇺) • BPI (🇺🇸) • TÜV AUSTRIA Certification:OK Compost HOME/INDUSTRIAL | Trust through certification |

| End Product | CO₂, H₂O, biomass (quality not guaranteed) | Nutrient-rich compost (safe for agriculture) | Useful output ensured |

Biodegradable plastic bags > Compostable bags (Compostable bags are a strict subset of biodegradable plastic bags that meet premium standards)

Related Artical: 2025 What Is the Difference Between Biodegradable and Compostable

Are Biodegradable Plastic Bags Compostable

“Biodegradable” does not equal “compostable.” Most “biodegradable” bags do not meet composting standards (degrading too slowly or leaving behind toxins). Composting requires industrial composting equipment, which adheres to strict temperature, humidity, and oxygen requirements.

All compostable bags certified by authoritative organizations are biodegradable plastic bags, but most biodegradable plastic bags cannot be called compostable.

Advantages and Disadvantages of Biodegradable Plastic Bags

Advantages of Biodegradable Plastic Bags

- Reduced Carbon Emissions: Made from plant-based materials, they emit less carbon during the composting process.

- Reduced Energy Consumption: Requires less energy and fossil fuels, reducing environmental pollution.

- Environmentally Friendly Processing: Decomposes under appropriate conditions, reducing landfill waste and environmental pollution.

- Recyclable: Some biodegradable plastics can be further recycled into new plastic products without harmful chemicals.

- Supports Sustainable Development: Reduces dependence on fossil fuels and reduces the accumulation of plastic waste in landfills and the natural environment.

Disadvantages of Biodegradable Plastic Bags

- Requires specific degradation conditions: Biodegradable plastics require specific environmental factors, such as temperature, humidity, and microbial activity, to degrade properly. In environments like landfills, they can take a long time to degrade or may not degrade at all.

- Long decomposition time: Some biodegradable plastics can take months to degrade, taking longer than expected. Improper composting can reduce their environmental benefits.

- High production costs: The production process requires more labor and uses more expensive plant-based raw materials, resulting in higher costs.

- Potential recycling disruption: Conventional plastic recycling processes may contaminate the recycling process or reduce the quality of the recycled material.

- Contamination risk: Improper handling and mixing with regular plastics can lead to contamination, making them unrecyclable.

- Toxicity concerns: The additives used in biodegradable plastics may, in some cases, be toxic to ecosystems or human health, although this is still under investigation.

How to Manufacture Biodegradable Plastic Bags

1.Raw Material Selection

Bio based or biodegradable polymers, rather than traditional polyethylene (PE), are used.

| Material | Key Properties | Source |

|---|---|---|

| PLA | Rigid, transparent, but brittle; requires modification for flexibility | Synthesized from corn/sugarcane starch via fermentation |

| PBAT | Flexible, PE-like softness; often blended with PLA to improve toughness | Fossil-based or partially bio-based (e.g., from renewable oils) |

| PBS | High heat resistance and strength | Succinic acid + butanediol (bio-based or fossil-based) |

| PHA | 100% bio-based, degrades in soil/ocean; high cost (~5x PLA) | Produced by microbial fermentation (e.g., from plant sugars) |

| Starch Blends | Low cost; requires blending with PLA/PBAT for strength (max 20-30% starch) | Potato/corn starch + biodegradable polymers |

2.Extrusion

The pellets are heated and melted, then pushed through a screw and extruded through a die into a plastic film or sheet, creating a continuous tube. The die is designed based on the specific shape and size of the bag.

3.Cooling

The film expands into a balloon shape. The extruded material is then cooled, stretched (to improve clarity and mechanical properties), and cut into bag shapes. This stage is related to the thickness, width, and strength of the bag.

4.Printing

Environmentally friendly water-based gravure printing is used, with up to eight colors possible, ensuring clear logos and preventing fading.

5.Cutting and Sealing

The printed film is cut into the required lengths by a machine, and the sides and bottom of the bag are heat-sealed to ensure leak-proofing. Some bags may also have gussets added for increased capacity.

6.Quality Inspection, and Packaging

The materials are then processed into bags (e.g., laminating and sealing), and quality inspection is completed to ensure compliance with national and international compostability standards (e.g., EN 13432 and GB/T 38082-2019). Finally, packaging is performed.

Who Invented Biodegradable Plastic Bags

There is no single, recognized “inventor.”

- Chilean researchers Roberto Astete and Cristian Olivares developed a water-soluble biodegradable plastic bag.

- Martinus Beijerinck’s bacterial research in 1888 and Maurice Lemoyne’s discovery of naturally biodegradable polymers in 1926.

- In 1973, British chemist G.J.L. Griffin patented starch-filled polyethylene plastic.

- In 1983, ICI founded Marlborough Biopolymers, which produced one of the first widely used biodegradable plastics, made from PHB and PHV, at a high cost.

- In the 1960s, Imperial Chemical Industries (ICI) successfully produced PHB in the 1970s.

- Monsanto further advanced bioplastic production in the 1990s.

- In the early 1990s, Italian chemist Katia Bastioli invented Mater-Bi, a biodegradable plastic derived from agricultural products designed for applications such as compostable bags. Filipino student Amin Hataman invented a biodegradable plastic bag made from nata de cocoa (a coconut byproduct);

- India’s Ashwath Hegde is working on a starch-based biodegradable bag;

- Scientists in Bangladesh and Chile have developed alternative biodegradable materials.

How Long Do Biodegradable Plastic Bags Take to Decompose

Degradation Time in Landfills

The oxygen-deficient environment of landfills causes biodegradable plastics to decompose extremely slowly. Anaerobic decomposition may also produce methane, a potent greenhouse gas, causing further environmental pollution.

Degradation Time in the Natural Environment (Ocean/Soil)

Common materials like PLA degrade just as slowly as traditional plastics in natural environments with low temperatures and low microbial content, such as seawater, rivers, or natural soil. This degradation can take decades or even centuries. Physical wear and tear can lead to the formation of large amounts of microplastics, posing a long-term threat to soil and aquatic ecosystems.

Degradation Time in Home Composting

Most products on the market are industrial compost standards, requiring sustained high temperatures to decompose. The temperature and microbial conditions in home composting bins are far from industrial-grade. These plastic bags won’t break down in them for months or even a year, potentially contaminating the composted product.

| Environmental Condition | Certified Compostable Bags | Oxo-Degradable (Pseudo-Degradable) Bags | Traditional PE Bags |

|---|---|---|---|

| Industrial Composting (58℃) | Degrade in 3-6 months | Fragment but do not fully degrade | Do not degrade |

| Home Composting (25-30℃) | Degrade in 6-12 months | Take over 5 years to degrade | Over 400 years |

| Seawater (15℃) | Over 5 years (PHA degrades 90% in 2 years, PLA cost 5x higher) | Over 10 years | Over 400 years |

| Landfill (Anaerobic) | Produces methane | Causes microplastic pollution | Does not degrade |

2019 American Chemical Society Experimental

Related Artical: 2025 Gudie : How Long Does It Take for Biodegradable Plastic to Decompose

Where Can I Buy Biodegradable Plastic Bags

- Offline Shopping: Biodegradable trash bags and biodegradable bags are available at grocery stores, supermarkets, and pharmacies.

- Online Shopping:Online marketplaces like Amazon and Alibaba offer a wide variety of biodegradable and compostable plastic bags from various manufacturers.

- Web Search: Search for local retailers specializing in organic or eco-friendly products to find biodegradable bags.

How Much Does It Cost to Make Biodegradable Plastic Bags

| Cost Component | Traditional PE Bags | Certified Biodegradable Bags | Cost Variance Reason |

|---|---|---|---|

| Raw Material Cost | ¥8-10/kg | ¥20-35/kg | PLA/PBAT priced 2-4× higher than PE resin |

| Processing Energy | ¥0.02/bag | ¥0.03-0.05/bag | 30% lower efficiency in low-temperature blown film processing |

| Certification Fees | None | ¥0.01-0.02/bag | EN 13432 compliance testing costs ¥150,000+ per batch |

| Total Cost per Bag | ¥0.08 | ¥0.25-0.45 | 3-5× price increase vs. conventional PE |

How Effective Is It to Use Biodegradable Plastic Bags

| Indicator | Traditional PE Bags | Certified Compostable Bags | Oxo-Degradable Bags |

|---|---|---|---|

| Load Capacity | Excellent (≥10 kg) | Good (5-8 kg) | Poor (3-5 kg) |

| Shelf Life | >5 years | 6-12 months | 9-15 months |

| Heat Resistance | Stable at 80°C | Softens >50°C | Brittles >60°C |

| Texture/Clarity | Smooth, High Transparency | Slightly tacky, Mild Haze | Similar to PE |

| User Pain Points | N/A | Brittleness (PLA crystallization) 20-30% lower heat-seal strength vs. PE | Fragmentation into microplastics |

How to Identify Biodegradable Plastic Bags

1.Certification Marks

Valid Certifications:

- Seedling (EU Industrial Composting)

- OK Compost HOME (Home Composting)

- BPI (USA)

Invalid Marks:

- “Degradable”/”Biodegradable” without a certification code

- Leaf icon without the certification body’s abbreviation (e.g., TÜV)

2.Material Testing

Flammability Test: Compostable bags have a yellowish flame and a caramelized smell (PLA); PE bags have a blue flame and a paraffin smell

Sinking Test: PLA/PBAT bags have a density >1g/cm³ (sinking); PE has a density of 0.92g/cm³ (floating)

3.Registration Inquiry

- China: Log in to the Light Industry Plastic Degradable Label Inquiry Platform to verify your company registration number

- EU: Verify your certificate number through TÜV AUSTRIA and the BPI (https://bpiworld.org/find-certified-products) official website. Our bags are biodegradable and compostable, and have passed EN13432/ASTM D6400/OK Compost multiple certifications. You can find our company identification number: 10529118 on the BPI official website.

Are biodegradable plastic bags good for the environment

Favorable Scenarios:

- Regions with industrial composting facilities (such as the EU/Japan): Degradation into CO₂ + H₂O + humus (toxicity tests meet standards)

- Replacement for agricultural mulch: PBAT/PLA mulch has a soil degradation rate of ≥90% in 6 months (data from the Chinese Academy of Agricultural Sciences)

Harmful Scenarios:

- Incorporation into plastic recycling streams: Contaminates recycled PE; a 1% content can cause the entire batch of recycled material to become brittle and scrapped.

- Ocean/landfill environments: Anaerobic decomposition produces methane (a greenhouse gas with a 28-fold greater impact than CO₂).

- Fragmentation into microplastics (PLA particles remain in soil for >3 years, according to a study by Wageningen University in the Netherlands).

- Fragmentation into microplastics (PLA particles remain in soil for >3 years, according to a study by Wageningen University in the Netherlands).

- The harsh reality: Only 12% of cities globally have industrial composting facilities (2024 Circular Economy data).

Are biodegradable plastic bags really biodegradable

| Type | Truly Biodegradable? | Key Evidence |

|---|---|---|

| Certified Compostable Bags | Yes | Complies with EN 13432: ≥90% degradation within 180 days in industrial composting |

| Oxo-Degradable Bags (OXO) | No | Banned in EU (Directive 2019/904) – fragment into microplastics |

| Uncertified “Degradable” Bags | High Risk | 78% contain PE + pro-oxidants (Tsinghua University Study, 2023) |

“In uncontrolled environments, most commercially available ‘biodegradable bags’ degrade at rates no different from those of conventional plastics.”

—Science, 2023 Global Assessment of Degradable Plastics (https://www.sciencedirect.com/science/article/pii/S0959652623041586)

FAQ

Are biodegradable plastic bags really better than plastic

Often considered more environmentally friendly, they contribute significantly to environmental waste in industrial composting environments, but can be counterproductive in landfills.

Are HDPE plastic bags biodegradable

HDPE (high-density polyethylene) bags are typically traditional plastics and are non-biodegradable. They resist microbial breakdown and persist in the environment for hundreds of years. Without modification or additives to promote degradation, standard HDPE bags do not biodegrade.

Can biodegradable plastic bags be recycled

Biodegradable plastic bags are generally not suitable for recycling. They can contaminate the recycling process.Composting is generally the preferred method for disposing of biodegradable and compostable plastic bags. Richard Thompson, a marine biologist at the University of Plymouth and senior author of the study, presented the results of an experiment.

Do biodegradable plastic bags harm wildlife

They generally reduce the risk of long-term contamination. However, if biodegradable plastic bags fail to fully degrade due to inappropriate environmental conditions, or if they fragment but do not fully decompose, they may pose a risk of ingestion or entanglement to wildlife.

Conclusion

Now you have a certain understanding of What are Biodegradable Plastic Bags, We must clearly recognize that biodegradable plastic bags are far from a panacea for the plastic crisis. True environmental protection lies in the simplest source reduction (Reduce) and reuse (Reuse). Reusable shopping bags and durable baskets achieve environmental benefits throughout their lifecycles that are unmatched by any disposable bag marketed as “environmentally friendly.”