If you’ve ever picked up a “biodegradable straw” or a takeout box labeled “compostable,” you’ve probably asked yourself the same question: “Does this stuff really decompose?” you might assume that after use, they’ll simply disappear into the trash like leaves. However, compostable plastics don’t work that way.

2025 will be a landmark year for the packaging, food delivery, and environmental protection industries. Regulations on plastics are becoming increasingly stringent in various countries, companies are continuously improving their ESG metrics, and consumers’ expectations for “green materials” have reached unprecedented levels.

As a manufacturer of biodegradable compostable bags for 16 years, we’ll guide you through the essentials of “What is compostable plastic?”—from basic definitions to the latest trends, from materials technology to industry applications, from certification systems to common misconceptions. Whether you’re a consumer, business owner, policymaker, or environmental enthusiast, this guide will help you make smarter, more sustainable, and more compliant choices.

What is Compostable Plastic

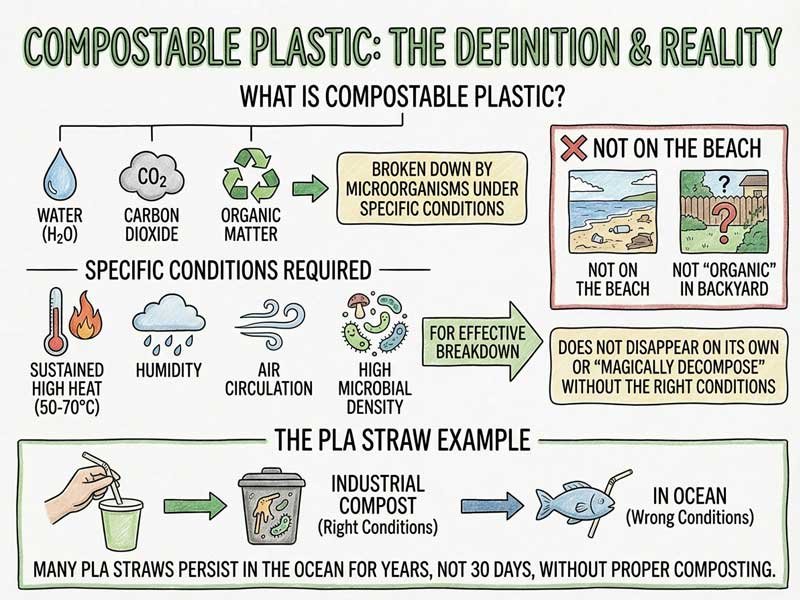

Compostable plastics are defined as materials that can be broken down into water, carbon dioxide, and organic matter by microorganisms under specific composting conditions. These conditions typically include stable high temperature, high humidity, and good air circulation—far more demanding than those in ordinary soil or landfills.

It won’t disappear on the beach on its own, nor will it “magically” decompose in your backyard. It requires specific conditions.

These include:

- Sustained high temperatures (50–70°C)

- Humidity

- Air circulation

- High density of microbial activity

This is why many PLA straws will float in the ocean for years, rather than “decomposing in 30 days.”

Compostable vs Biodegradable vs Recyclable

- Compostable: Decomposes completely into harmless substances in a composting environment.

- Biodegradable: Theoretically decomposes eventually, but this could take decades, or even be impossible under certain conditions.

- Recyclable: Does not decompose, but can be reprocessed into new products.

The easiest way to remember this is:

- Compostable = consumed by microorganisms;

- Biodegradable = “may turn into small fragments”;

- Recyclable = continues to be used as plastic, just with a different purpose.

To learn more about the differences between biodegradable and compostable products, you can read this article:Compostable vs Biodegradable: 2025 Comprehensive Guide

Compostable plastics commonly seen in our daily lives include:

- PLA straws: Used in many coffee shops, but they require an industrial composting environment to decompose.

- Compostable takeout containers: Lightweight and resembling paper, but they don’t decompose simply by being tossed onto the grass.

- Compostable coffee cup lids: Usually made of PLA or similar materials, but still subject to temperature and humidity requirements.

These products are indeed more environmentally friendly than traditional plastics, but their environmental value only truly exists when they are disposed of “in the right place”.

Why Compostable Plastics Matter in 2025

Comprehensive Regulatory Upgrades

- EU: SUPD and new packaging regulations promote the application of compostable materials.

- China: Strengthening policies to reduce plastic use in food delivery, express delivery, and fresh food packaging.

- US: Multiple cities ban single-use plastics.

- Southeast Asia: From “plastic waste importer” to environmental legislation.

Regulations are forcing companies to change, and compostable materials have become a dual solution for both “compliance” and “brand image.”

Changing Consumer Demands

More and more people are willing to pay for more environmentally friendly options. They are not only concerned with “how well a product works,” but also with:

- Is the packaging green?

- Does the company have environmental awareness?

- Are the materials sustainable?

Increased ESG Pressure on Brands

Food delivery platforms, food companies, and e-commerce sellers are all growing under ESG scrutiny.

Compostable plastics have become an important tool for:

- Reducing carbon emissions

- Reducing solid waste

- Enhancing brand value.

What Is Compostable Plastic Made Of

When we talk about “compostable plastics,” we’re actually referring to different types of materials. Their sources, properties, decomposition rates, and suitable applications all differ. If you’re involved in procurement, product development, or simply want to know which is the most environmentally friendly, the following section will be particularly helpful.

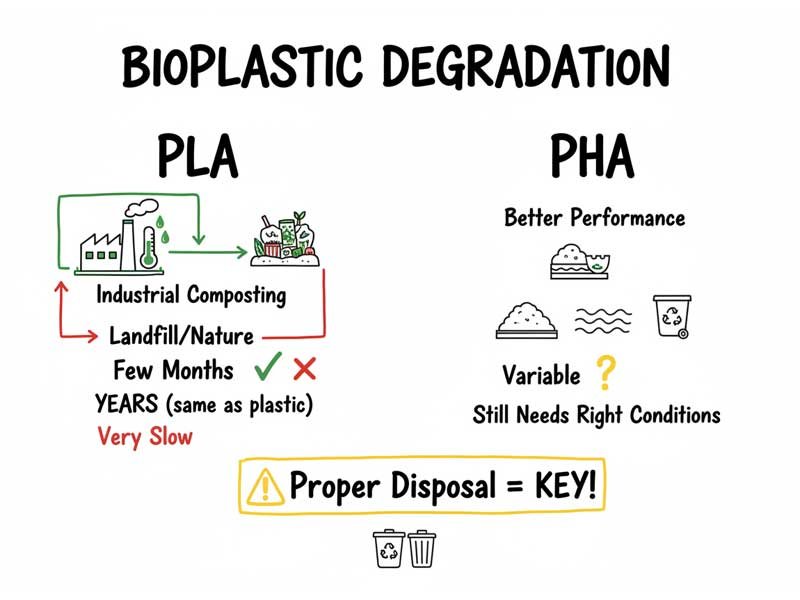

PLA (Polylactic Acid)

PLA is one of the most common, lowest-cost, and most widely used compostable materials on the market. It comes from plant starches—usually corn, sugarcane, or cassava—which sounds very “natural.”

You’ll often see PLA in takeout packaging, coffee cup lids, straws, transparent cups, and 3D printing materials.

PLA requires extremely high temperatures in industrial composting environments to decompose completely.

It won’t disappear automatically in soil.

It hardly decomposes in marine environments.

Throwing it in a recycling bin will contaminate the entire batch of recyclable plastics.

PLA is well-suited for areas with well-developed industrial processing systems, but not for those expecting it to decompose easily.

PHA (Polyhydroxyalkanoates)

PHA is the “gold standard” in the compostable plastics world. It’s not made from plants, but rather a natural polymer produced through microbial fermentation. Simply put, it’s a “cultivated environmentally friendly material.”

The biggest highlights are:

- It can decompose in marine environments (few materials can do this)

- It truly leaves no microplastics

- It has extremely low ecotoxicity

Therefore, many environmental organizations highly recommend PHA.

However, it also has two practical problems: high cost and insufficient supply scale.

You can often find PHA in high-end straws, biomedical materials, disposable tableware, etc.

PBS (Polybutylene Succinate)

PBS is a highly heat-resistant, stable, and easy-to-process compostable material, which is particularly popular in the industrial field.

Advantages include:

- Processability close to traditional plastics

- Good mechanical strength

- Can be blended with other materials (such as PLA) to improve heat resistance

- Suitable for thick-walled, heat-resistant products, such as packaging films and injection-molded products

PBS is often combined with other biomaterials to improve overall performance and is an important member of the “industrial-grade compostable plastics” category.

Emerging Materials: Seaweed, Mycelium, Bamboo Fiber

By 2025, a number of new sustainable materials are rapidly emerging. These materials are not only environmentally friendly but also create unique visual and tactile differentiation for brands.

Seaweed-based materials

- Abundant raw materials, rapid regeneration

- Can be made into films and food packaging

- Mycelium

- Used fungal mycelium to grow into “packaging shapes”

- Replaces foam and cushioning materials

- Can be composted at home

Bamboo fiber

- Extremely fast growth rate

Suitable for dry food packaging, takeaway bowls, and cups

These materials help brands create a “more natural, lower-carbon, and more unique” product image, making them ideal for companies looking to differentiate themselves.

What Is Compostable Plastic Examples

Compostable plastic products are gradually entering our daily lives, especially in the food service, packaging, and agriculture sectors.

- Disposable tableware, cups, and straws: Many restaurants and cafes are starting to use compostable tableware and cups as alternatives to traditional plastics.

- Garbage bags and food waste bags: Compostable garbage bags and organic garbage bags can be incorporated into composting systems along with food scraps.

- Agricultural mulch film: Used for agricultural covering, it can be plowed directly into the soil and does not require recycling.

- Some food packaging: Such as coffee capsules and snack packaging liners.

- Baby diapers, wipes, and other hygiene products: Some products are exploring the use of compostable materials.

Advantages and Disadvantages of Compostable Plastics

Advantages:

- Reduced Plastic Pollution: With proper waste management systems, compostable plastics can effectively reduce the accumulation of traditional plastics in the natural environment, thus mitigating environmental impact.

- Reduced Resource Consumption: Some bio-based compostable plastics use renewable resources such as corn and sugarcane as raw materials, helping to reduce dependence on finite fossil fuels.

- Produces Beneficial Compost: Its decomposition products are organic-rich compost, which can improve soil quality and promote a circular economy.

Disadvantages and Limitations:

Despite its many advantages, compostable plastics are not without challenges.

- Insufficient Infrastructure: Globally, industrial composting facilities capable of processing compostable plastics remain scarce, representing the biggest obstacle to the widespread adoption of this sustainable solution.

- Potential for Recycling Contamination: If compostable plastics are mistakenly disposed of in traditional plastic recycling bins, their chemical composition differs from ordinary plastics, contaminating the entire recycling batch and rendering them unrecyclable. Therefore, the answer to whether it is recyclable is “no.”

- Higher Cost: Compared to traditional petroleum-based plastics, the production of compostable plastics cost is generally higher, limiting their large-scale application.

- Not a “panacea”: Even compostable plastics are still single-use products. Best environmental practices remain prioritizing reusable products and adhering to the principles of reduction and reuse.

- Carbon footprint: The agricultural activities and processing required to produce bio-based compostable plastics also generate carbon emissions, which need to be fully measured through life cycle assessments.

How Does Compostable Plastic Work

Decomposition Mechanism:

The decomposition of compostable plastics is a biological process. Under suitable temperature, humidity, and oxygen conditions, microorganisms (such as bacteria and fungi) break down the polymer structure, converting it into simpler molecules, ultimately becoming water, carbon dioxide, and organic-rich biomass—what we call compost.

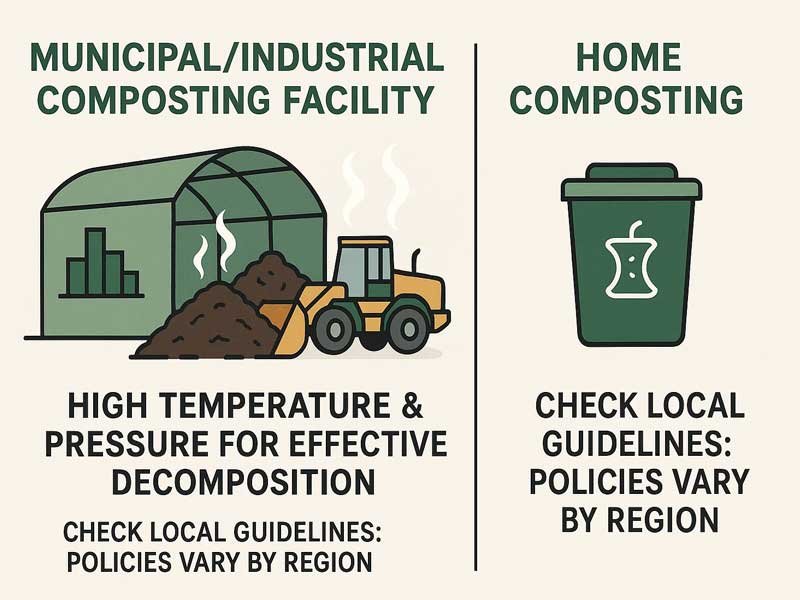

Industrial Composting vs. Home Composting:

Understanding the differences between these two composting facilities is key to properly handling compostable plastics.

- Industrial Composting: Most compostable plastics are designed for industrial composting facilities. These facilities maintain consistently high temperatures (typically exceeding 55°C) and strictly controlled humidity and ventilation. In such an ideal environment, microbial activity is extremely high, allowing compostable plastics to decompose rapidly and thoroughly, typically within 90-180 days.

- Home Composting: Home composting conditions are generally far less stable and ideal than industrial composting. Temperatures are lower, and humidity and ventilation are difficult to control precisely. Only a small number of compostable plastic products explicitly labeled “Home Compost Certified” can effectively decompose in home compost bins. Most common compostable plastics decompose very slowly or not at all in a home composting environment.

- Misconception: Many people mistakenly believe that as long as a product is “compostable,” it can be directly thrown into their backyard compost bin. However, this is often incorrect.

Microplastic Residue Issues:

True, certified compostable plastics that decompose completely in industrial composting facilities should, in theory, leave no microplastics. Their decomposition products are non-toxic and can dissolve in the soil.

The challenge is that if compostable plastics fail to decompose completely under ideal conditions (e.g., in uncertified home composting or accidentally dumped in landfills), tiny fragments may remain, which could be mistaken for microplastics.

Current scientific research is still exploring the behavior and long-term effects of these incompletely decomposed bioplastic fragments in the environment. Therefore, proper handling is key to avoiding potential problems.

Decomposition Time:

In an ideal industrial composting environment, compostable plastics typically decompose within 3 to 6 months. In home composting, however, this process can take much longer, even over a year, and the decomposition may be incomplete.

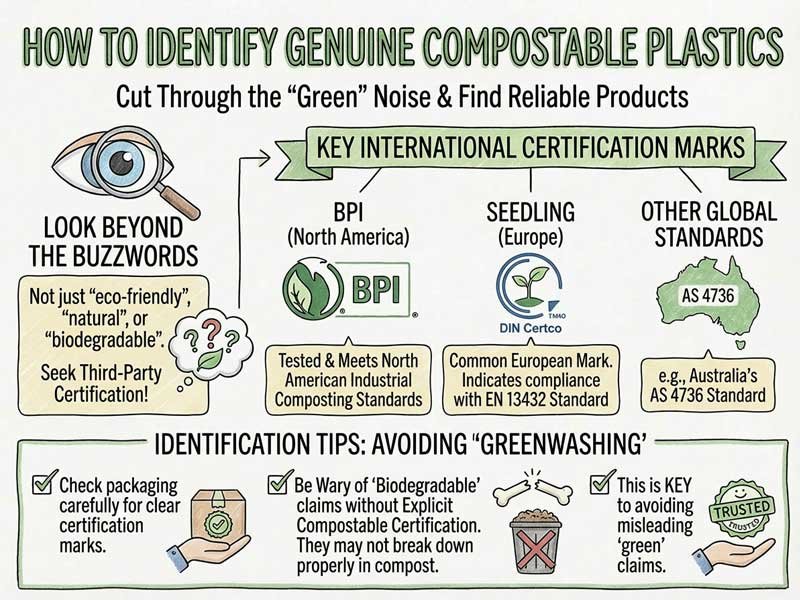

How to Identify Genuine Compostable Plastics?

Because the concept of “green plastics” is often confusing in the market, learning to identify genuine compostable plastic products is crucial. You need to look for clear third-party certification marks, not just vague terms like “eco-friendly,” “natural,” or “biodegradable.”

Important International Certification Standards and Marks:

- BPI (Biodegradable Products Institute – North America): If a product bears the BPI certification mark, it means it has passed rigorous testing and meets the decomposition standards of North American industrial composting facilities.

- Seedling Logo (Europe): This is one of the most common compostable certification marks in Europe, usually certified by organizations such as DIN Certco, indicating that the product complies with the European EN 13432 compostable plastics standard.

- Standards in Other Countries: For example, the Australian AS 4736 standard.

Identification Tips:

When purchasing, always carefully examine the product packaging. Genuine compostable plastics will clearly display their certification marks. If a product claims to be “biodegradable” but does not have the above or equivalent explicit compostable plastic certification, it is likely not capable of completely decomposing in a composting environment. This is a crucial step in avoiding “green cleaning”.

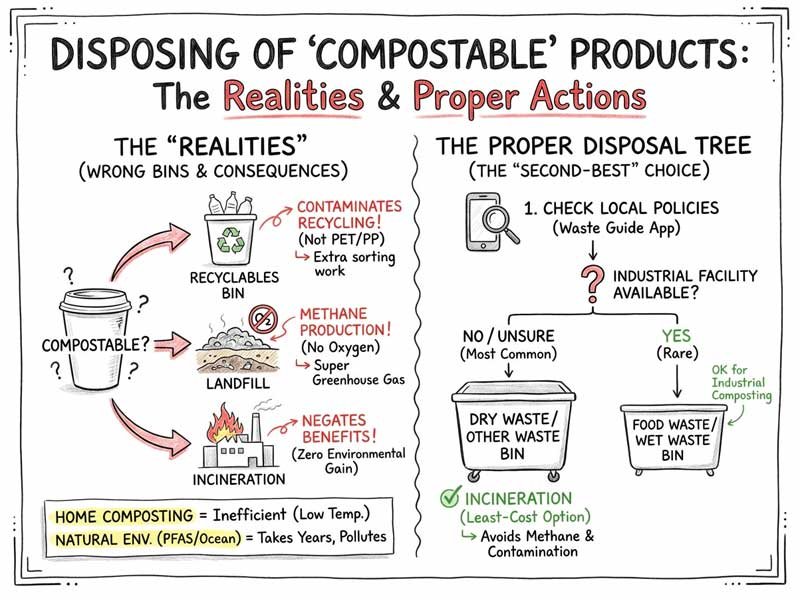

How to Dispose of Compostable Plastic

Proper disposal of compostable plastics is key to realizing their environmental benefits. Incorrect sorting and disposal can actually create more problems.

Core Principle:

Always “check the label to understand the processing capacity in your area.” Don’t assume that because it’s “environmentally friendly,” you can just throw it away anywhere.

Best Disposal Options:

A. Industrial Composting Facilities: This is the best destination for most compostable plastics.

How to find industrial composting facilities in your city?

- Visit the official websites of your city or region’s environmental protection department or waste disposal service provider.

- Search “[Your City Name] + Industrial Composting Facilities” or “[Your City Name] + Food Waste Recycling”.

- Some environmental organizations or professional composting associations may provide online maps or databases.

- If found: Strictly follow the facility’s regulations for sorting and disposal. This may mean putting it in a dedicated collection bin with food waste.

B. Home Composting (only products certified for home composting):

How to identify? Look for a clear “Home Compost” certification mark on the product packaging. If only the “Industrial Compost” label is present, it is not suitable for home composting.

Note: Home composting decomposes more slowly and may take longer. Ensure your compost bin is properly maintained (e.g., maintain adequate moisture, turn it regularly to increase oxygen, and reach a suitable temperature).

If composting is not possible:

Unfortunately, if your area lacks available composting facilities, or if the product is not suitable for home composting, its environmental value will be significantly reduced.

Never throw it into a conventional plastic recycling bin: This is the most common mistake and disastrous! Compostable plastics have a different chemical composition than conventional plastics. If mixed into the recycling stream, they will contaminate the entire batch, rendering conventional plastics unrecyclable. Remember: Compostable plastic is not the same as recyclable plastic.

Final fate: In most cases, it can only be disposed of as regular waste in landfills or incinerated.

Is it better than conventional plastic in the “worst-case scenario”? In landfills, some bio-based compostable plastics may produce methane (a potent greenhouse gas) unless the landfill has a methane collection system. When incinerated, the energy and emissions produced may differ from those of conventional plastics. However, without composting, its so-called “environmental advantages” are almost entirely lost.

The Importance of Consumer Education:

Proper sorting and disposal, rather than simply purchasing, is key to realizing the true environmental benefits of compostable plastics. We need to raise public awareness and understand the waste management requirements for different types of plastics.

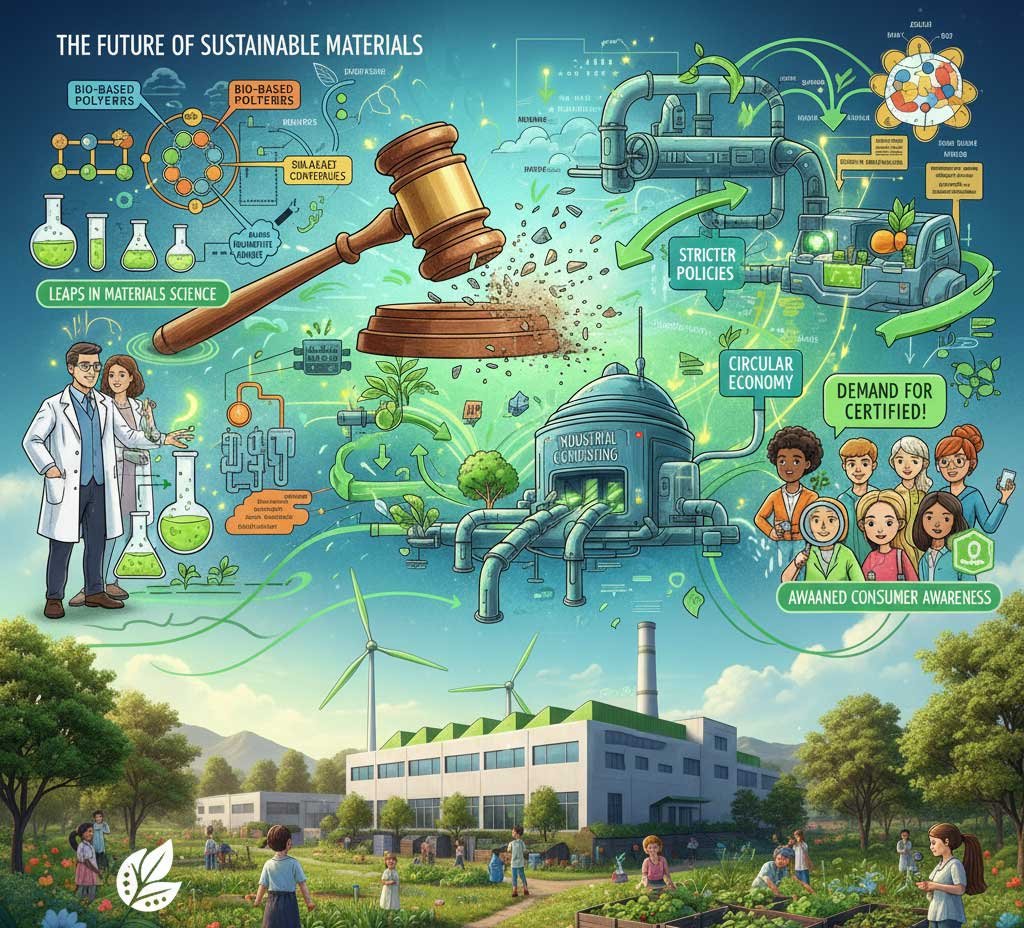

The Future of Compostable Plastics: Can They Solve the Plastic Crisis?

Compostable plastics undoubtedly offer a promising alternative and sustainable solution to the plastic crisis, but they are not a panacea.

- Challenges and Opportunities:

- Lack of Infrastructure: The global lack of sufficient industrial composting facilities is the biggest bottleneck to their widespread adoption. Investing in waste infrastructure is crucial.

- Cost and Scale of Production: Reducing the production cost of compostable materials and achieving large-scale production are key to driving market penetration.

- Public Education and Awareness Building: Addressing insufficient consumer education and classification confusion requires joint efforts from governments, businesses, and the public.

- New Material R&D and Technological Advancement: Continuous innovation is needed to develop bioplastics that decompose effectively in a wider range of environments and have a lower carbon footprint.

- Macro Perspective:

Compostable plastics are part of a sustainable plastic ecosystem under the circular economy concept, but they are by no means the only one, nor the most important. We must always adhere to:

- Reduce: Reduce all unnecessary consumption, especially single-use items.

- Reuse: Reuse products as much as possible to extend their life cycle.

- Recycle: Ensures conventional plastics enter the correct recycling stream to avoid pollution.

- Compost: For truly compostable organic waste.

- Industry Development Trends:

Driven by policy support (such as the EU’s Green New Deal), technological innovation, and growing consumer demand, the compostable plastics industry is steadily developing. In the future, its potential will be further realized as waste management systems become smarter and more efficient.

FAQ

Is Compostable Plastic Recyclable

No.

What is compostable plastic made of?

Plant-based materials, such as corn, sugarcane, and microbial fermentation products.

Is compostable plastic better for the environment?

When properly handled, it is more environmentally friendly than conventional plastics—provided it enters a composting system.

Can compostable plastic break down in the ocean?

Most, except for a few PHAs, cannot.

Is PLA truly compostable?

Yes, but requires industrial composting conditions.

Conclusion

This article has explored the potential of compostable plastics as an environmentally friendly alternative that can help reduce the environmental impact of traditional plastics. However, it is not a “get-out-of-jail-free card,” and its true environmental benefits depend heavily on proper identification and disposal.

Related Articles