AS5810 Home Compostable Certification: The Ultimate Guide

This page provides a compliance-level explanation of the Australian AS 5810 home compostable certification.

Table of Contents

It explains what the standard covers, which products can qualify, how certification is verified, and how AS 5810 differs from AS 4736 and EN 13432 in real-world use.

AS 5810 is Australia’s official standard for home compostable plastics and packaging.

It defines whether a product can safely break down in backyard and household composting systems, without requiring industrial heat or controlled processing.

Many buyers, brands, and importers confuse AS 5810 with industrial composting standards such as AS 4736 or EN 13432.

This misunderstanding often leads to incorrect product claims, rejected packaging, or compliance risks.

This guide explains what AS 5810 certification means, when it applies, how it is verified, and where its limits are—so businesses can make compliant decisions when sourcing compostable bags and packaging for Australia.

What is AS5810 Home Compostable Certification

AS 5810 is the Australian standard for home compostable plastics.

It evaluates whether a finished product can decompose safely in low-temperature, unmanaged household composting environments.

To pass AS 5810, a product must demonstrate:

- Effective biodegradation at ambient temperatures

- Physical disintegration without persistent residues

- No negative impact on compost quality or plant growth

- Compliance with strict heavy metal and chemical limits

AS 5810 applies to the finished product, not just raw materials.

Why Is AS 5810 Considered a Strict Standard?

Home composting environments are far less controlled than industrial composting facilities.

Temperatures are lower, moisture varies, and microbial activity is inconsistent.

AS 5810 was designed to reflect these real conditions.

A product that passes AS 5810 must break down without relying on industrial heat, machinery, or active management.

This makes AS 5810 one of the strictest compostability standards globally.

Is AS5810 legally mandatory in Australia?

AS 5810 is not universally mandated by law, but it is widely required in practice.

Whether AS 5810 is required depends on:

- How the product is marketed (e.g. “home compostable” claims)

- Retailer or marketplace requirements

- Council or state-level waste and packaging policies

For products marketed as home compostable, AS 5810 is generally treated as the reference standard during audits and compliance reviews.

How AS 5810 Fits into Australia’s Packaging Compliance Framework

AS 5810 supports broader Australian packaging and sustainability requirements, including:

1. APCO Sustainable Packaging Guidelines (SPG)

APCO recognizes compostable claims only when supported by certification such as AS 5810 or AS 4736, along with correct labeling and disposal guidance.

2. National Packaging Targets

Home compostable packaging contributes to waste reduction and organic recovery targets, especially where industrial composting access is limited.

3. EPR and Retail Audits

Verified certification, traceable documentation, and correct logo usage help reduce greenwashing risk and audit failures.

Which Products Can Qualify for AS 5810 Certification?

AS 5810 applies to a wide range of home compostable products, including:

- Kitchen caddy liners

- Compostable garbage and bin liners

- Retail shopping and carry bags

- E-commerce mailers

- Pet waste bags (subject to local disposal rules)

- Food-contact films, labels, and lightweight packaging components

Certification depends on product structure, thickness, inks, adhesives, and additives.

Passing once does not guarantee future compliance if specifications change.

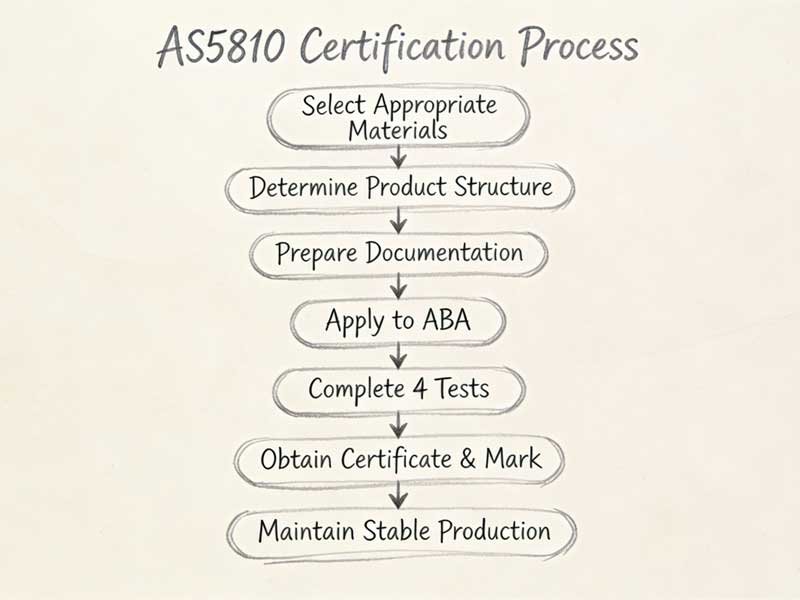

How AS 5810 Certification Works (High-Level)

The AS 5810 certification process typically includes:

-

Finalizing product specifications

-

Submitting samples and documentation

-

Biodegradation testing

-

Disintegration testing

-

Ecotoxicity and chemical safety evaluation

-

Certification approval and listing

Certification is issued only after all requirements are met under defined test conditions.

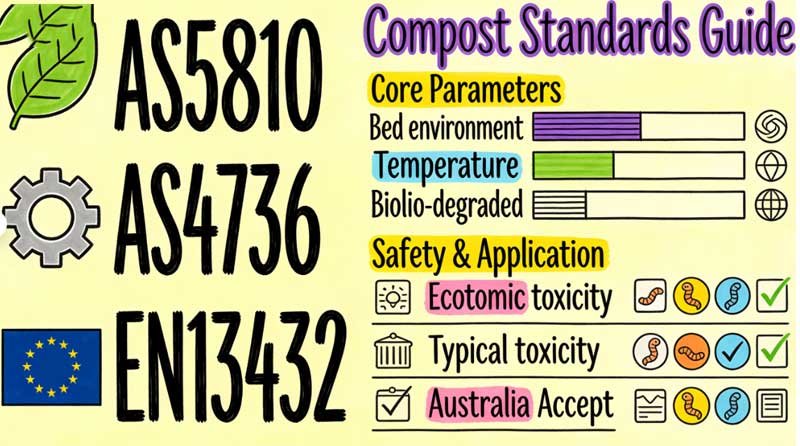

AS 5810 vs AS 4736 vs EN 13432

These standards are often confused, but they serve different systems:

-

AS 5810 → Home composting (Australia)

-

AS 4736 → Industrial composting (Australia)

-

EN 13432 → Industrial composting (Europe)

A product certified for industrial composting does not automatically qualify for home composting.

For a system-based explanation, see: Home Composting vs Industrial Composting: Key Differences Explained

Can AS 5810 Bags Be Used in FOGO Bins?

Certification does not guarantee acceptance in all waste systems.

Some councils accept AS 5810-certified bags, while others restrict any bags in FOGO collections due to contamination or policy concerns.

Acceptance depends on local council rules, not certification alone.

Users should always check local FOGO guidelines.

Common Misunderstandings About AS 5810

-

“Home compostable means it breaks down everywhere”

-

“AS 5810 replaces industrial standards”

-

“Certification guarantees performance in landfill or nature”

AS 5810 applies only to home composting under suitable conditions.

Limitations of AS 5810 Certification

AS 5810 certification does not guarantee:

-

Breakdown in landfill environments

-

Degradation in marine or natural ecosystems

-

Acceptance in all municipal composting programs

-

High durability comparable to conventional plastics

Certification confirms compostability under defined test conditions—not universal disposal outcomes.

Key Takeaways

- AS 5810 is Australia’s home compostable standard

- It applies to finished products, not materials alone

- Home and industrial composting are not interchangeable

- Certification defines where compostable claims are valid

- Local waste system acceptance still matters

Understanding AS 5810 helps reduce compliance risk, prevent misleading claims, and ensure packaging is matched to the correct composting system.