When you see packaging labeled “EN 13432 certified” in the supermarket, do you know what it means? Is it just a code on the back of the bag? The EN 13432 standard is more than just a number. It’s Europe’s leading industrial standard for compostable packaging. It sets clear rules to ensure that products labeled “compostable” can truly decompose under suitable conditions and safely return to nature.

In this article, I will explain the EN 13432 standard in a simple and easy-to-understand way. I will focus on the requirements of the standard, what it doesn’t guarantee, and how to apply it when selecting or designing compostable packaging.

What Is EN 13432?

The full name is “Requirements, test protocols and final acceptance criteria for compostable and biodegradable packaging,” but it is commonly referred to as EN 13432 or the European compostability standard.

If a bag, film, or container claims to be compostable within the EU, it must comply with EN 13432. Otherwise, the claim cannot be used.

You can think of EN 13432 as the common language for compostable packaging in Europe. It helps ensure that packaging does not become a long-term burden but can be converted to compost in industrial composting systems.

Why is EN 13432 Certification Important?

EN 13432 is an official European standard for compostable packaging materials, applicable in Germany, France, and Italy. The full name of EN 13432 is “Packaging – Recyclable packaging by means of composting and biodegradation requirements, through an evaluation and testing scheme,” and it was developed by the European Committee for Standardization (CEN) to define “compostable.”

If a bag, film, or container claims to be compostable in the EU, it must pass the EN 13432 test. Otherwise, it cannot legally use the label.

- It’s legally required to claim “compostable” in the EU.

- It helps your packaging meet EU Directive 94/62/EC on packaging waste.

- It builds credibility with buyers, distributors, and consumers.

- It protects your brand from greenwashing accusations.

Key Requirements of the EN 13432 Standard

The EN 13432 standard has four main requirements.

These are the core tests you will see in every technical description of compostable materials.

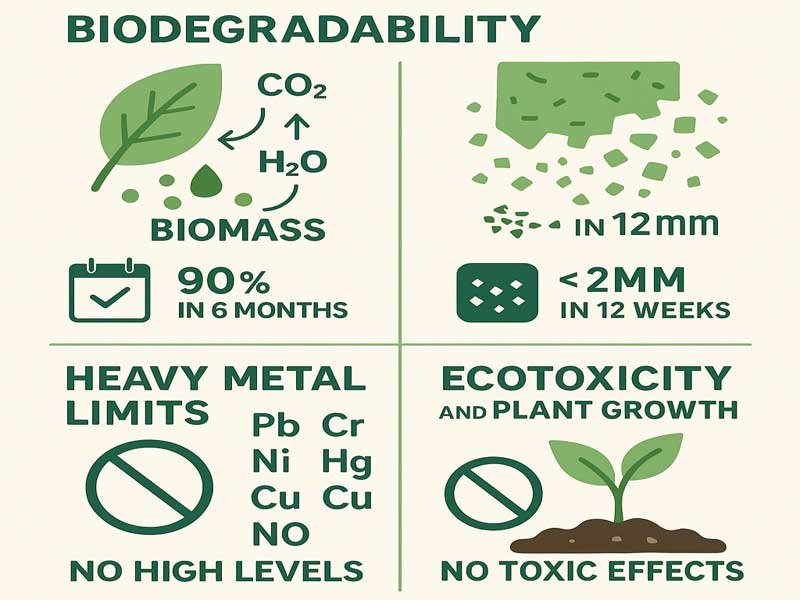

1) Biodegradability

The material must break down into:

- carbon dioxide

- water

- biomass

At least 90% of the material must biodegrade within six months under industrial composting conditions.

2) Disintegration

The product must physically break apart.

After twelve weeks, the pieces must be smaller than 2 mm.

This helps ensure that the compost looks and feels like compost, not like shredded plastic.

3) Heavy Metal Limits

The material cannot contain high levels of metals such as:

- lead

- chromium

- nickel

- mercury

- copper

These limits protect soil quality.

4) Ecotoxicity and Plant Growth

The compost made from the material must:

- stay safe for soil and organisms

- support normal plant growth

- show no toxic effects

This test helps confirm that the material returns to nature without harm.

These four requirements appear again and again in discussions of the EN 13432 standard and are the foundation of Europe’s compostable packaging rules.

Industrial Composting and What the EN 13432 Standard Assumes

The EN 13432 standard is built for industrial composting, not home compost.

Industrial facilities use:

- high heat (often 55–70°C)

- controlled moisture

- controlled aeration

- active microbial systems

These conditions allow materials to break down much faster than they would in a backyard compost pile.

Many people ask:

“If a product meets the EN 13432 standard, can I compost it at home?” The honest answer is no. Home composting conditions vary too much in temperature, moisture, and oxygen.

This is why the EN 13432 standard is only for industrial composting.

EN 13432 Certified Products

You’ll find this certification on a wide range of eco products:

- Compostable bags: Film bags used in supermarkets to hold fruits and vegetables; shopping bags provided by retailers when purchasing clothing.

- Cuisine and takeout containers: Plates, cutlery, cups, and takeout containers made from corn starch (PLA), bagasse, or other bio-based materials, used in takeout, parties, or fast food restaurants.

- Coffee cups and lids: Compostable coffee cups, typically using a bio-based coating to ensure the entire cup (including the lid) decomposes in industrial compost.

- Agricultural film: Films and containers used for covering crops or making seedling cups

- Tea bags and coffee capsules

- Labels and tape: Packaging labels and tapes

To check if something is truly certified, look for:

- The “EN 13432” mark, or The OK Compost Industrial logo

You can verify certificates directly from TÜV Austria’s database or DIN CERTCO.

What the EN 13432 Standard Does NOT Guarantee

This is where many misunderstandings start.

I see questions about this often, especially in online discussions.

The EN 13432 standard does not guarantee that a material will:

- break down in home compost

- break down in soil

- break down in landfills

- break down in the ocean

- decompose in places with low heat or poor aeration

It also does not guarantee that every industrial composting facility will accept the material.

Some facilities have shorter composting cycles than the standard’s test conditions.

Understanding these limits helps avoid unrealistic expectations.

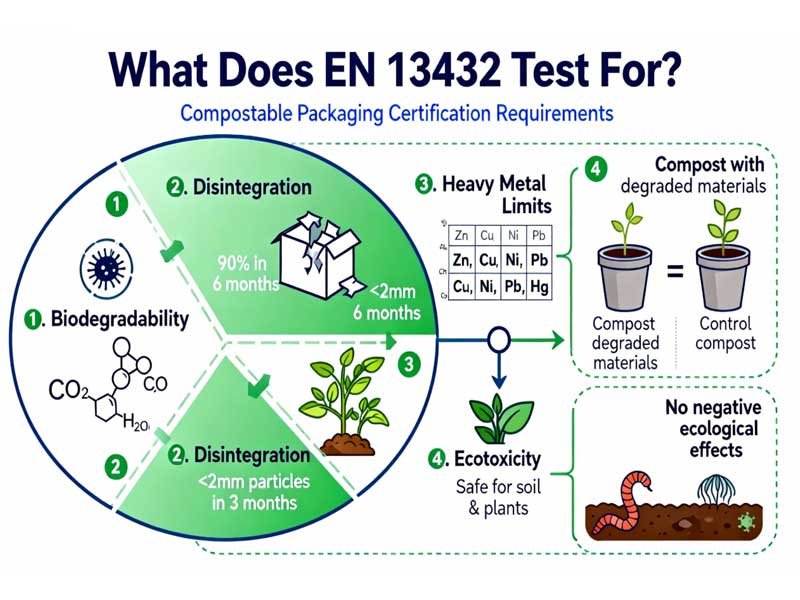

What Does EN 13432 Test For?

EN 13432 standard focuses not only on the decomposition of materials. It also examines whether materials can safely return to nature without leaving any harmful residues.

EN 13432 certification requirements:

Biodegradability :In an industrial composting environment, 90% of the material must be decomposed and transformed into simpler, harmless substances, primarily carbon dioxide (CO2), water (H2O), and biomass, within 6 months by microorganisms (such as bacteria and fungi).

Decomposition :The product packaging must be physically broken down into tiny, imperceptible fragments (less than 2 mm) within 3 months (12 weeks).

Heavy metal content limits:The content of zinc, copper, nickel, lead, and mercury must be strictly controlled within certain limits (usually below 250 mg/kg).

Ecotoxicity: It must be able to be converted into high-quality compost with normal organic waste and must be beneficial to plant health. No toxic residues are allowed.

- Plant growth trials: Scientists compare compost containing degraded packaging materials with compost without them, planting the same plants (such as corn or watercress). If the compost containing degradation products supports healthy plant growth and shows no significant difference from the control group, it is considered passed.

- Ecotoxicity testing: This assesses the compost’s impact on soil microorganisms or other organisms (such as earthworms) to ensure that degradation products do not produce negative ecological effects.

In other words: Composting can only proceed if it has been proven safe for soil

How Buyers and Brands Can Use the EN 13432 Standard

If you work with compostable packaging, the EN 13432 standard can help you make better choices.

Here are practical steps that buyers often take:

- Check if the final product (not just the material) meets the EN 13432 standard.

- Read test reports carefully. Look for biodegradability, disintegration, heavy metals, and ecotoxicity results.

- Confirm whether printing inks and glues also meet compostability requirements.

- Ask suppliers if each layer of a multi-layer product meets the EN 13432 standard.

- Verify certificate numbers through official databases when needed.

These steps help prevent confusion between “compostable-looking” products and products that actually follow the EN 13432 standard.

Industrial Composting vs. Home Composting:

When discussing compostable packaging, a common question is, “Can I compost these at home?” This leads to an important distinction: industrial composting versus home composting. EN 13432 primarily addresses the former, and for a reason.

EN 13432 and Industrial Composting Environments: Why Specialized Facilities Are Needed

Industrial composting facilities are not your small compost bin in your backyard. They are large, specialized centers designed to process large quantities of organic waste quickly and efficiently. These facilities create ideal composting conditions:

- High Temperature: Industrial composting systems can maintain high temperatures (typically between 55-70°C) for extended periods. This high temperature is crucial for rapid material decomposition, accelerating microbial activity.

- High Humidity: Humidity is also precisely controlled, providing a favorable working environment for microorganisms.

- Microbial Control: Engineers ensure a suitable microbial community exists in the compost pile, the primary force in decomposing the material.

- Ventilation: Regular turning or forced ventilation ensures an adequate oxygen supply, as EN 13432 tests for aerobic biodegradation.

Because of these controlled and optimized conditions, EN 13432 can set requirements for decomposition within a short timeframe (e.g., 90% biodegradation within 180 days, 90% disintegration into small fragments within 3 months). My experience tells me that if these biodegradable plastics are placed in ordinary home compost, they may take much longer, or even fail to decompose completely. This is why EN 13432 specifically emphasizes industrial composting environments.

Home Composting Standards: Certifications such as “OK Compost HOME”

Of course, there are also standards and certifications designed for home composting environments. For example, TÜV AUSTRIA’s OK Compost HOME certification is specifically designed for materials that can decompose at lower, more unstable temperatures (such as in our own backyard compost bins). This standard is usually more stringent than EN 13432 because home composting environments have large temperature variations, inconsistent humidity, and lack professional management. Therefore, if a product has the “OK Compost HOME” label, it’s much more likely to decompose in a home compost bin.

Consumer Education:

This is an important tip for me: when you see a product labeled “compostable,” stop and think. It likely refers to industrial composting. This means you need to dispose of it in a dedicated industrial composting bin, not your own garden compost bin. If there’s no local industrial composting facility, these compostable packages may end up in a landfill or incinerator, losing their intended environmental value. Therefore, consumer education is crucial; we should all understand how to properly dispose of these eco-friendly packages to truly benefit from them.

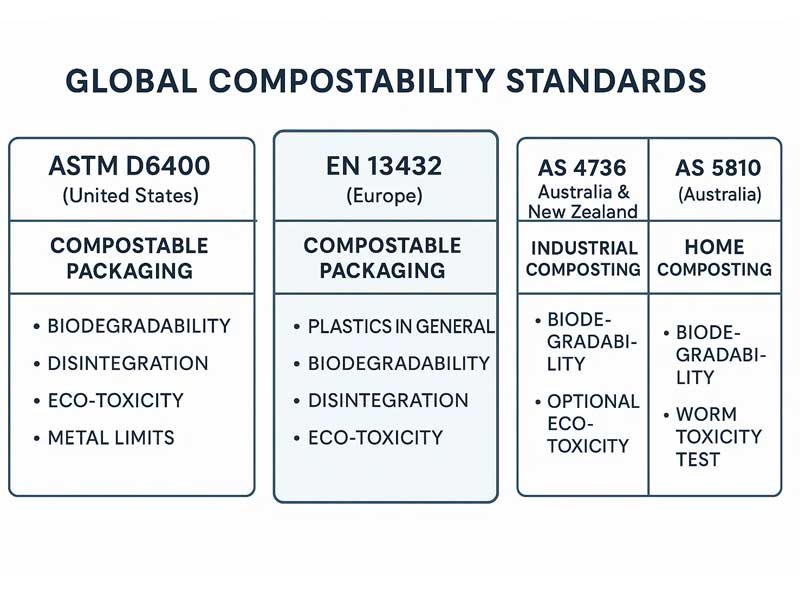

EN 13432 Standard Compared With Other Compostability Standards

Different regions use different compostability standards.

Here is a simple way to see the EN 13432 standard in context.

EN 13432 (Europe)

- For compostable packaging

- Industrial composting

- Requires biodegradability, disintegration, eco-toxicity, and metal limits

ASTM D6400 (United States)

- Similar to EN 13432

- Industrial composting

- Eco-toxicity testing is optional

EN 14995 (Europe)

- Similar technical requirements to EN 13432

- Applies to plastics in general, not just packaging

AS 4736 (Australia & New Zealand)

- Based on EN 13432

- Adds a worm toxicity test

AS 5810 (Australia)

- For home composting, not industrial composting

These comparisons help people see how the EN 13432 standard fits within global compostability rules.

Global Compostability Standard Map

A simple way to understand compostability rules is to look at them by region.

- Europe: EN 13432, EN 14995

- United States & Canada: ASTM D6400, ASTM D6868

- Australia & New Zealand: AS 4736 (industrial), AS 5810 (home)

- International: ISO 17088

Many materials used worldwide reference more than one standard. This helps companies sell products in multiple markets.

Common Misunderstandings About EN 13432

EN 13432 = Biodegradable

False. Biodegradable ≠ compostable. EN 13432 defines full compostability, not just degradation.

EN 13432 Products Decompose Anywhere

False. Only under industrial composting conditions (not in soil, landfill, or ocean).

EN 13432 Certification Is Optional

False. It’s required in the EU if you want to label your product “compostable.”

FAQ

Is EN 13432 the same as “industrial compostable”?

Yes. The EN 13432 standard is based on industrial composting conditions.

Is EN 13432 required in Europe?

If a product claims to be compostable in the EU, it must follow the EN 13432 standard.

Does the EN 13432 standard mean a product is biodegradable?

Yes, but only under industrial composting conditions.

This does not mean it will biodegrade in home compost or natural environments.

Can EN 13432 packaging break down in home compost?

No. Home composting conditions are too variable.

What is the difference between EN 13432 and ASTM D6400?

Both are compostability standards for industrial composting.

EN 13432 includes required eco-toxicity tests, while ASTM D6400 does not always require them.

When to Read More About the EN 13432 Certification Process

This page explains the EN 13432 standard itself.

If you want to learn about certification, testing steps, or how companies prove that a product meets EN 13432, you can read our EN 13432 Certification Page.

Conclusion

The EN 13432 standard is more than a code on a label. It is a technical framework that explains what “compostable packaging” must do inside an industrial composting system. When you understand this standard, you can read compostability claims more carefully, ask better questions as a buyer or brand owner, and choose packaging that fits real composting conditions—not just marketing language. For anyone working toward sustainable packaging, knowing how the EN 13432 standard works is a solid starting point. It will not solve every waste problem, but it gives everyone a clear and shared set of rules to follow.

Source:

European Standard EN 13432 Summary – European Committee for Standardization (CEN)