OK Compost Certification: Home & Industrial Guide for Brands and Buyers

Table of Contents

Quick Answer

OK Compost Certification in 30 seconds

- OK Compost INDUSTRIAL: certified for industrial composting (aligned with EN 13432).

- OK Compost HOME: certified for home composting at lower temperatures (harder to achieve).

- How to verify: check the certificate number in the TÜV Austria OK database.

OK Compost Certification is a compostability label issued by TÜV Austria.

It helps buyers confirm that a product is tested and certified for composting—either in industrial facilities (OK Compost INDUSTRIAL) or in backyard conditions (OK Compost HOME).

As a compostable bag manufacturer working with TÜV Austria standards on a daily basis, I’ve learned that many buyers recognize the OK Compost logo—but few truly understand what it guarantees, and what it does not.

I wrote this guide to help buyers, brands, and distributors make informed decisions when sourcing certified compostable bags.

Who This OK Compost Guide Is For

I wrote this guide with real users in mind:

Buyers and procurement managers

Retail and private-label brands in Europe

Distributors and importers of compostable bags

Municipal and FOGO program managers

Manufacturers planning to apply for certification

If you make decisions about sustainable packaging, you will find what you need here.

What Is OK Compost Certification?

OK Compost Certification is a compostability label issued by TÜV Austria, one of the most trusted certification bodies in Europe.

The goal of this certification is to confirm that a product can safely break down in a composting system.

There are two types:

OK Compost INDUSTRIAL

For products that break down in industrial composting facilities with high temperatures.

OK Compost HOME

For products that break down in a home compost system, which runs at lower temperatures.

Both labels test:

Biodegradation

Disintegration

Ecotoxicity

Heavy metal limits

But OK Compost HOME has stricter requirements because home composting is slower and less controlled.

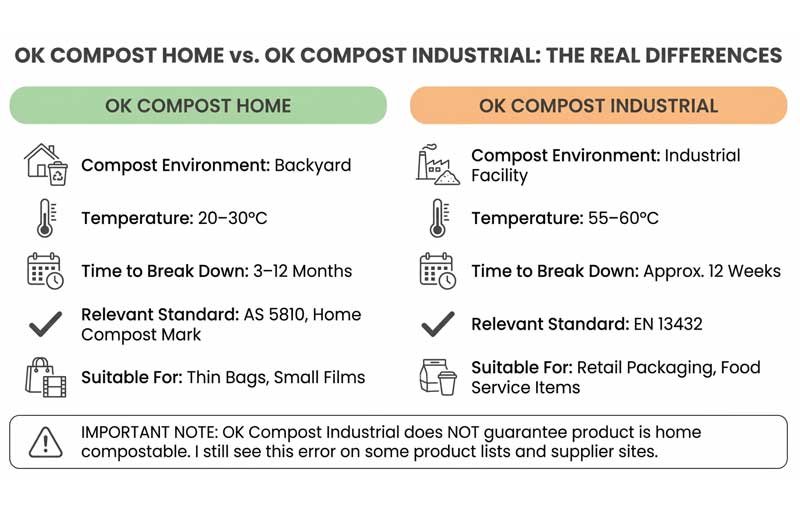

OK Compost HOME vs INDUSTRIAL: The Real Differences

| Feature | OK Compost HOME | OK Compost INDUSTRIAL |

|---|---|---|

| Composting environment | Backyard | Industrial facility |

| Temperature | 20–30°C | 55–60°C |

| Time to break down | 3–12 months | ~12 weeks |

| Related standard | AS 5810, home compost logos | EN 13432 |

| Suitable for | Thin bags, small films | Retail packaging, food service items |

Important:

OK Compost Industrial does not guarantee home compostability.

I still see this mistake on product listings and supplier websites.

OK Compost in the Global Compostable Certification Landscape

Europe

EN 13432 (standard)

OK Compost HOME / INDUSTRIAL (certification marks)

USA / Canada

BPI Certification

ASTM D6400 / ASTM D6868

Australia / New Zealand

AS 4736 (industrial)

AS 5810 (home)

How global brands combine these

A simple example:

Selling in EU → OK Compost + EN 13432

Selling in the US → BPI + ASTM D6400

Selling in AU/NZ → AS 4736 + AS 5810

As a manufacturer exporting worldwide, I often advise buyers to map certifications to markets like this.

Why OK Compost Certification Matters for EU Compliance

While OK Compost certification is a voluntary label, it plays an increasingly important role in helping brands comply with European environmental regulations. In the EU, sustainability claims such as “compostable,” “biodegradable,” or “environmentally friendly” must be supported by verifiable scientific evidence — and OK Compost certification is one of the most widely recognized ways to demonstrate that proof.

Below is a clear explanation of how OK Compost fits into the European regulatory landscape and why brands rely on it to avoid compliance risks.

1. Link to the EU Packaging and Packaging Waste Directive (PPWD)

The EU Packaging and Packaging Waste Directive defines the legal framework for packaging placed on the European market. When a product is marketed as “compostable,” the Directive requires that:

- The packaging must comply with EN 13432, the harmonized standard for industrial compostability.

- The claim must be supported by third-party certification or test reports.

- Retailers and importers must be able to verify that environmental claims are accurate.

OK Compost Industrial certification is directly aligned with EN 13432.

This makes OK Compost one of the most accepted labels within the EU for demonstrating compliance with industrial compostability requirements.

2. EU Green Claims Regulation (Avoiding Greenwashing)

Europe is tightening rules against misleading environmental claims (“greenwashing”). Under the upcoming EU Green Claims Regulation:

Brands must provide scientific proof for terms such as:

- “compostable”

- “biodegradable”

- “eco-friendly”

- “plastic-free”

Without third-party certification like OK Compost, brands risk:

Fines from local consumer authorities

Product removal from retail chains

Negative audit results in supplier evaluations

Legal challenges from consumer protection agencies

OK Compost certification protects brands by providing verified, test-based evidence that a product can compost safely and completely.

3. Why Retailers in Europe Prefer OK Compost Certified Packaging

Large European retailers — especially supermarket chains and private-label brands — often require suppliers to use recognized compostability logos for packaging placed in compostable waste streams.

Reasons retailers prefer OK Compost certification include:

Ensures product compliance across all EU markets

Simplifies supplier verification

Reduces risk of incorrect environmental claims

Aligns with their sustainability commitments (ESG reporting)

Improves consumer trust and sorting accuracy

Without visible certification, packaging may be rejected during audits.

4. Role of OK Compost in FOGO Programs and Municipal Composting Requirements

Across Europe, more cities are adopting FOGO (Food Organics & Garden Organics) programs.

Many municipal composting facilities only accept packaging that:

carries the OK Compost Industrial logo, or

passes EN 13432 certification

This is because uncertified packaging increases contamination and reduces compost quality.

Examples of acceptance rules:

- Some municipalities accept only OK Compost Industrial / EN 13432 certified liners

- Some accept no packaging at all

- Very few accept home-compostable packaging due to lower processing temperatures

Brands targeting FOGO or circular-waste markets must use recognized certification marks.

5. Why OK Compost HOME Is Becoming More Important in EU Markets

Although industrial composting is more common, home composting is rising in popularity, especially in:

- France

- Italy

- Belgium

- The Netherlands

As home garden composting becomes a household trend, buyers increasingly prefer packaging labeled:

OK Compost HOME

because it provides:

- true low-temperature biodegradation

- safety in backyard compost systems

- a more consumer-friendly sustainability message

Many eco-focused brands use OK Compost HOME to add value to premium product lines.

6. How OK Compost Supports EPR (Extended Producer Responsibility) Compliance

Under EPR systems, producers pay fees based on the environmental impact of their packaging.

In some EU countries:

- Certified compostable packaging may receive lower eco-modulation fees,

- Non-certified “biodegradable” packaging may receive penalties due to contamination risks.

OK Compost certification provides:

- clear documentation for EPR submissions

- compliance evidence for product stewardship schemes

- traceability required for environmental audits

This makes OK Compost useful not only for marketing, but also for regulatory reporting.

Why OK Compost Matters for Compliance

For brands:

- Prevents greenwashing

- Simplifies EU-wide legal compliance

- Improves audit success with retailers

For distributors:

- Ensures product claims match certification

- Reduces liability

- Supports transparent communication with customers

For manufacturers:

- Proves technical capability

- Increases acceptance in global markets

- Aligns with international compostability systems

OK Compost certification is more than a logo — it is a trusted indicator of regulatory compliance, product safety, and environmental responsibility.

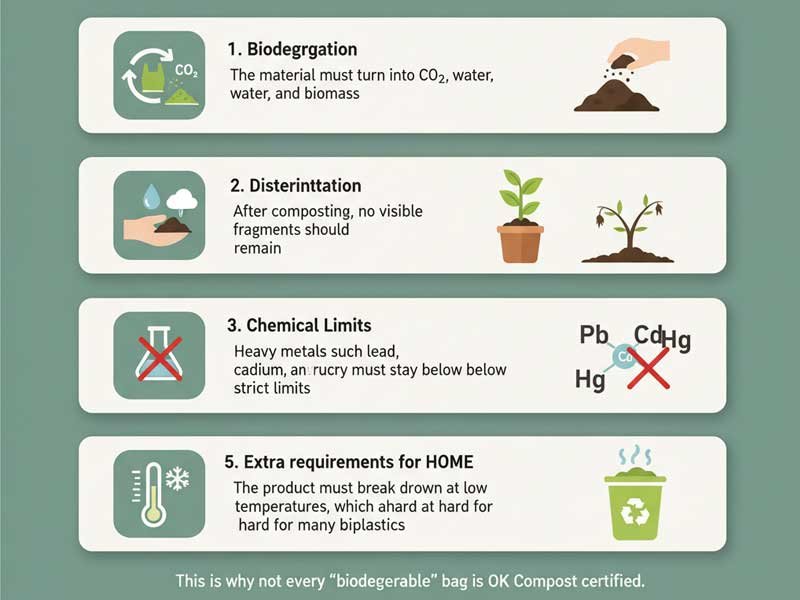

What Does OK Compost Certification Test?

TÜV Austria follows strict rules that match EN 13432 and additional requirements for home compost.

1. Biodegradation

The material must turn into CO₂, water, and biomass.

2. Disintegration

After composting, no visible fragments should remain.

3. Ecotoxicity

The resulting compost must support healthy plant growth.

4. Chemical limits

Heavy metals such as lead, cadmium, and mercury must stay below strict limits.

5. Extra requirements for HOME

The product must break down at low temperatures, which is hard for many bioplastics.

This is why not every “biodegradable” bag is OK Compost certified.

OK Compost Certification Costs: What You Should Budget For

Many brands and manufacturers underestimate the cost and time required for OK Compost certification. TÜV Austria follows strict test procedures for both OK Compost INDUSTRIAL and OK Compost HOME, and the total cost varies depending on product complexity, material formulation, and the number of SKUs being certified.

Below is a practical breakdown of the expenses you should expect when planning OK Compost certification.

Typical Certification Cost Breakdown

| Cost Component | What It Covers | Typical Range |

|---|---|---|

| Application Fee | Document review, formulation assessment, initial preparation | €300 – €1,200 |

| Laboratory Testing Fee | Biodegradation, disintegration, ecotoxicity, chemical tests | €6,000 – €14,000+ |

| Additional Retesting Fee | Required when samples fail or need repeats | €1,500 – €5,000 |

| License / Logo Usage Fee | Permission to use OK Compost INDUSTRIAL or HOME logo | €1,000 – €3,000 per year |

| Certificate Renewal Fee | Renewal every 3–5 years depending on certification scope | Similar to initial test cost |

Important:

OK Compost HOME is always more expensive and more difficult to achieve than INDUSTRIAL, due to lower-temperature testing and more stringent disintegration requirements.

Why Certification Costs Vary So Much

The final cost depends heavily on the product type:

Thickness

Thicker products take longer to degrade and may require repeated tests.

Multi-Layer Structures

Every layer must be compostable.

If one layer fails → the entire product fails.

Additives, Inks, Colorants

Non-compliant pigments or coatings often cause ecotoxicity failures.

Different SKUs or Sizes

If multiple product sizes use different thicknesses or materials, they may need separate certifications.

HOME Certification Complexity

Home composting requires breakdown at 20–30°C, making it much harder for PLA/PBAT blends.

Only certain grades (e.g., high-PHA content) typically pass.

Typical Cost Examples (Based on Real Projects)

| Product Type | OK Compost Industrial | OK Compost Home |

|---|---|---|

| Thin produce bags | €7,000 – €10,000 | €12,000 – €18,000 |

| Dog waste bags | €6,000 – €9,000 | Rarely suitable unless very thin |

| Shopping bags | €8,000 – €12,000 | Difficult due to thickness |

| Multi-layer mailer bags | €10,000 – €15,000 | Usually not eligible |

| Compostable resin | €5,000 – €8,000 | Not applicable (HOME rarely granted) |

Why Certification Costs Should Be Seen as an Investment

For brands selling in Europe:

OK Compost logos increase consumer trust

Retailers prefer certified packaging

It reduces risk of greenwashing allegations

Waste facilities can accept certified products more easily

Enhances ESG documentation & transparency

For manufacturers:

Certification allows you to expand into new markets

Simplifies compliance for buyers

Helps avoid costly retesting later

When used correctly, certification can significantly increase the value of your product line and open up new retail channels.

How to Reduce the Cost of OK Compost Certification

Use certified base materials when possible

This reduces risk but does not guarantee final product approval.

Standardize product thickness

Multiple thicknesses = multiple test samples = higher cost.

Avoid complex multi-layer structures

Simple mono-layer films perform better in disintegration tests.

Pre-test materials internally

A small-scale compost test can save thousands of euros by identifying obvious issues early.

If you are unsure whether your product is a good candidate for OK Compost certification, we can help you review materials, thickness, and design to estimate cost and feasibility before applying.

Which Products and Materials Can Be OK Compost Certified?

Finished products

TÜV Austria certifies finished items, such as:

- Compostable trash bags

- Shopping bags

- Produce bags

- Mailer bags

- Dog waste bags

- Food service packaging

Raw materials

Sometimes suppliers only certify the resin or film.

This can be misleading for buyers if they think the final bag is certified too.

Common materials that pass

- PLA + PBAT blends

- Starch-based films

- PHA (often used for home compostable grades)

Materials that struggle

- PLA + PBAT blends

- Starch-based films

- PHA (often used for home compostable grades)

- Pure PLA (needs high heat → usually industrial only)

If you buy compostable packaging, always check whether the bag itself is certified, not only the raw material.

Industries and Applications That Commonly Require OK Compost Certification

OK Compost certification is widely used across industries that rely on organic waste collection, sustainable packaging programs, or consumer-facing eco-labeling. Different sectors prefer either OK Compost INDUSTRIAL or OK Compost HOME, depending on their waste streams, customer expectations, and composting infrastructure.

Below is a comprehensive industry overview that reflects real buyer behavior and procurement requirements in Europe and global markets.

Here is a concise, simplified version of your content, keeping all key points and use cases clear and easy to understand:

1. Supermarkets & Grocery Retailers

European grocery chains prefer certified compostable packaging to meet sustainability goals and improve waste sorting.

Common uses: produce bags, biobased shopping bags, bakery packs, compostable pouches, labels.

Preferred certification:

Industrial for most operations

Home for premium organic/zero-waste products

Retailers often require visible OK Compost logos for audits.

2. Food Service, Restaurants & Coffee Chains

Cafés, QSRs, and delivery brands use compostable items to reduce plastic waste and meet ESG goals.

Products: compostable liners, takeaway boxes, cutlery, cups, wrappers.

Certification: Mostly Industrial; Home for small eco-friendly product lines.

3. Municipal FOGO Programs

Cities running industrial composting require certified bags to avoid contamination.

Uses: food waste liners, household bin liners, compostable labels.

Certification: Industrial only (strict requirement in many EU regions).

4. E-Commerce & Mailing Industry

Brands replace poly mailers with compostable alternatives.

Products: compostable mailers, envelopes, protective films.

Certification:

Industrial for durability

Home only for thin specialty films

OK Compost logos support eco-branding.

5. Pet Industry (Dog Waste Bags)

A major category for compostable film products.

Why certification matters: proof of no microplastics, retailer approval, some municipal acceptance.

Certification: Mainly Industrial; Home for niche eco-markets.

6. Household & Consumer Goods

Home composting drives demand for backyard-friendly packaging.

Products: cling film, small liners, caddy bags, organic product packaging.

Certification:

Home for zero-waste consumers

Industrial for general use

7. Agriculture, Landscaping & Horticulture

Used for plant waste and organic farming materials.

Applications: plant bags, mulch bags, harvest bags.

Certification: Mostly Industrial, with some Home for small consumer items.

8. Zero-Waste Stores & Sustainable Brands

Depend on certification for transparency and consumer trust.

Uses: refill bags, organic food packaging, customer bags.

Certification:

Home as a strong marketing advantage

Industrial for broader packaging needs

9. Events, Festivals & Public Venues

Compostable products support large-scale waste management.

Uses: cups, cutlery, wrappers, food scrap bags.

Certification: Industrial, due to bulk waste collection.

OK Compost logos improve sorting accuracy.

How to Verify OK Compost Certification (For Buyers)

Many buyers have asked me how to avoid “fake” certificates or misleading claims.

Here is the method I teach distributors and brand owners.

Step 1 — Ask for the certificate PDF

It must include:

- Certificate number

- Holder’s company name

- Product type

- Scope (e.g., “compostable bags made from PLA/PBAT film”)

- Validity period

Step 2 — Check TÜV Austria’s online database

If the product is not in the database, it is not certified.

Step 3 — Confirm it is a product-level certificate

A common red flag:

The resin is certified, but the finished bag is not.

This is one of the simplest ways buyers are misled.

Step 4 — Match the certificate with the exact product you are buying

Check:

- Bag thickness

- Color

- Application

- Material type

Step 5 — Warning signs (red flags)

- Supplier shares logo but no certificate

- Expired certificate

- Certificate issued to another company

- Certificate for pellets, but supplier sells finished bags

This section alone can save buyers from costly mistakes.

As a manufacturer, I always encourage buyers to verify any OK Compost logo they see. A real certificate stands up to scrutiny.

Red flags buyers should watch

- Supplier shows the logo but refuses to share a valid PDF certificate

- Certificate is expired or issued to another company

- Only the resin is certified, not the finished bag

- Product thickness/ink differs from certificate scope

When Should You Choose OK Compost HOME vs INDUSTRIAL?

For grocery & retail brands

- Produce bags : HOME or INDUSTRIAL

- Shopping bags : INDUSTRIAL is usually enough

- If your brand targets eco-focused consumers: HOME can add value

For pet brands (dog waste bags)

Most users will throw the bag in the regular trash.

So:

- INDUSTRIAL = more realistic

- HOME = for zero-waste markets or premium lines

For e-commerce mailers

Shipping conditions can be rough: humidity, pressure, time in transit.

- INDUSTRIAL is generally safer

- HOME requires very specific material blends and careful storage

For municipal FOGO programs

This depends on local rules.

Some EU cities only accept OK Compost Industrial / EN 13432 packaging.

Others accept no packaging at all.

OK Compost vs EN 13432 vs “Biodegradable” Logos

OK Compost vs EN 13432

- EN 13432 = the test standard

- OK Compost = the recognized logo

OK Compost vs “biodegradable”

“Biodegradable” has no clear time frame or conditions.

A biodegradable product can take years to break down and may leave microplastic.

Certified compostable products must pass strict tests.

Why brands prefer certified logos

- Avoid greenwashing

- Meet retailer requirements

- Support waste stream sorting

- Give buyers honest information

Our Experience as an OK Compost Certified Manufacturer

As a producer of compostable bags, I work with global buyers who need reliable documents and consistent quality. Here is what we provide:

Products we offer under OK Compost standards

- Trash bags

- Shopping bags

- Produce bags

- Dog waste bags

- Compostable films for packaging

How we support distributors and brand owners

- Provide certificate copies

- Provide technical data sheets

- Support printing and packaging design

- Help avoid incorrect claims on packaging

Documents you receive

- Certificate PDF

- Declaration of compliance

- Material information

- Logo usage guidance

Our goal is simple: make certification clear and honest.

How to Get OK Compost Certification (For Manufacturers or Brand Owners)

If you are a manufacturer or planning your own branded product, here is the basic process.

- Define the product (type, thickness, use)

- Submit samples to a TÜV-approved lab

- Biodegradation, disintegration, and toxicity tests

- Document review

- Certificate issue and logo approval

The full process takes several months.

Working with a manufacturer that already has certified products can save time.

If you work with a manufacturer that already holds OK Compost certified products, you can often avoid repeating the certification process from zero.

Common Misunderstandings About OK Compost

“OK Compost means it will break down anywhere.”

Not true. Composting needs oxygen and the right microbes.

“Industrial = Home compostable.”

No. Home composting requires lower temperatures.

“Resin certification = finished bag certification.”

Not correct. The final product must be tested.

“Plant-based always means compostable.”

Some plant-based plastics behave like regular plastics.

“OK Compost is mandatory in the EU.”

Not always. But many retailers prefer it.

OK Compost Certified vs Non-Certified Compostable Packaging

Not all “compostable” or “biodegradable” products behave the same way in real composting conditions. A product with OK Compost certification has been scientifically tested and verified, while many non-certified products rely on vague or unregulated environmental claims.

Below is a clear comparison to help brands, buyers, and distributors understand the difference — and why certification matters.

Certified vs Non-Certified: The Key Differences

| Feature | OK Compost Certified | Non-Certified “Compostable” Claims |

|---|---|---|

| Scientific Testing | ✔ Fully tested (biodegradation, disintegration, toxicity, chemicals) | ✖ No standardized testing required |

| Independent Verification | ✔ TÜV Austria approved laboratories | ✖ Supplier or manufacturer self-claims |

| Compliance with EN 13432 / EN 14995 | ✔ Meets EU legal compostability standards | ✖ No compliance proof |

| Guaranteed Breakdown Performance | ✔ Industrial or home composting verified | ✖ No guarantee; may take years to break down |

| Microplastic Safety | ✔ Must fully disintegrate with no residue | ✖ May leave microplastic fragments |

| Accepted by Composting Facilities | ✔ Widely accepted | ✖ Often rejected due to contamination risk |

| Retailer / Importer Approval | ✔ Supports audit & supplier verification | ✖ Poses compliance risks |

| Legal Protection for Eco-Claims | ✔ Complies with EU Green Claims Regulation | ✖ High risk of being considered greenwashing |

Why Non-Certified Compostable Products Create Problems

Problem 1 — They may not break down as claimed

Many products labeled “biodegradable” only break down under very specific conditions or over extremely long periods. Without OK Compost certification, buyers cannot be sure that the product will:

disintegrate within the required time

achieve full biodegradation

leave no harmful residue

This leads to contamination in compost and landfill streams.

Problem 2 — Composting facilities may reject them

Industrial composters must maintain strict quality controls.

Non-certified “compostable” bags are often banned because:

they slow down composting cycles

they leave visible fragments

they contaminate finished compost

they are visually indistinguishable from non-compostable plastics

Certified products help composters sort and process waste more efficiently.

Problem 3 — Retailers increasingly require certification

European retailers, especially supermarkets and private-label brands, are tightening requirements. Most now expect:

OK Compost Industrial

EN 13432 compliance

or equivalent third-party certificates

Non-certified products may fail supplier audits and risk being removed from shelves.

Problem 4 — High greenwashing risk

In the EU, misleading environmental claims can lead to:

regulatory fines

forced product relabeling

removal from the market

damage to brand credibility

Without certification, words like “compostable” or “biodegradable” are not legally defensible.

Problem 5 — Resin-level certification is not enough

Some suppliers show certifications for materials, not finished bags.

This is misleading because:

- thickness affects performance

- coatings and inks may not be compostable

- multi-layer structure changes degradation behavior

Only final products can be certified — not just raw materials.

Why OK Compost Certification Protects Your Business

Ensures transparency and trust

End users, retailers, and distributors can instantly verify certification online.

Helps pass retailer & importer audits

Certification supports compliance with European packaging and sustainability programs.

Reduces contamination in composting programs

Certified products match the processing requirements of industrial composting facilities.

Reduces legal and reputational risk

Brands are protected from greenwashing accusations and regulatory penalties.

Improves customer satisfaction

Consumers increasingly expect credible eco-labels, not vague claims.

Certified Products Support the Circular Economy

OK Compost certification ensures that products:

- break down under real composting conditions

- contribute to high-quality finished compost

- support food-waste collection systems

- minimize plastic pollution

This aligns with Europe’s circular economy goals and municipal waste strategies.

Why You Should Choose Certified Over Non-Certified

| Reason | Why It Matters |

|---|---|

| Proof of compostability | Scientific testing + independent verification |

| Reduced risk | Avoid greenwashing, audit failures, consumer complaints |

| Better performance | Tested to fully disintegrate without microplastics |

| Market acceptance | Required by many retailers, municipalities, and waste programs |

| Brand protection | Ensures accurate and defensible sustainability claims |

Typical Failure Scenarios and How to Avoid Them

Even well-designed compostable products can fail OK Compost certification for reasons that are easy to overlook. OK Compost INDUSTRIAL and especially OK Compost HOME follow strict test protocols, and small issues in material selection, formulation, or production design can lead to test failure or costly retesting.

Below are real-world scenarios we commonly see during certification projects — and how manufacturers and brands can avoid them.

These examples are simplified but reflect the typical challenges faced in TÜV Austria’s certification process.

Scenario 1 — Film Is Too Thick to Disintegrate Properly (Industrial or Home)

What happened:

A brand submitted compostable shopping bags for OK Compost INDUSTRIAL certification.

Although the material biodegraded well, the film thickness was too high, and after 12 weeks:

- more than 10% of material remained,

- visible pieces larger than 2 mm failed the disintegration criteria.

Why it failed:

Thicker films slow down fragmentation and microbial access.

How to avoid it:

- Reduce film thickness by 10–25% depending on resin type.

- Pre-test disintegration using small-scale composting before sending samples.

- Keep bag sizes and thicknesses consistent across SKUs (each thickness may require separate testing).

Scenario 2 — Printing Ink Contains Non-Compostable Components (Very Common)

What happened:

A supplier used regular flexo inks on compostable bags.

During certification, heavy metal limits (e.g., zinc or chromium) exceeded OK Compost requirements.

Why it failed:

Non-certified pigments, metallic inks, and certain dyes do not break down safely in compost.

How to avoid it:

- Use only TÜV-approved compostable ink systems.

- Request “ink compliance statements” from ink manufacturers.

- Avoid metallic, neon, and specialty-effect inks.

Ink-related failures are one of the most common causes of certification delays.

Scenario 3 — Resin Is Certified, but Finished Product Fails

(This is the #1 misunderstanding among buyers)

What happened:

A brand used a resin that was OK Compost Industrial certified.

However, after converting it into a mailer bag:

- the final structure included an adhesive and a coating,

- the finished product failed disintegration testing.

Why it failed:

Certification applies to finished products, not just the base resin.

Any added layer or component affects compostability.

How to avoid it:

- Ensure every layer (coating, adhesive, seal strip, colorant) is compostable.

- Avoid complex multi-layer structures for Industrial tests; for Home, they are rarely suitable.

- Verify additives and masterbatches before production.

Scenario 4 — Seal Strip or Adhesive is Not Compostable (Mailer Bags)

What happened:

Compostable mailer bags passed biodegradation and disintegration,

but the sealing strip adhesive did not break down at industrial composting temperatures.

Why it failed:

Adhesives often contain non-compostable polymers.

How to avoid it:

- Use compostable hot-melt adhesives verified for TÜV Austria certification.

- Ask suppliers for documented compostability of adhesives.

- Pre-test seal performance under composting conditions.

Mailer bags frequently fail because of adhesives — not the film.

Scenario 5 — Product Deforms or Clumps Together During Testing

What happened:

A compostable produce bag passed biodegradation but failed disintegration because it:

- melted slightly,

- clumped together,

- slowed down fragmentation.

Why it failed:

Some PLA/PBAT blends behave differently at 55–60°C (industrial compost temperatures).

If bags stick together, the composting process cannot access the inner layers.

How to avoid it:

- Use materials with lower melting points balanced for industrial compost setups.

- Reduce thickness or modify resin ratios.

- Add perforations to allow airflow and reduce clumping.

Scenario 6 — Material Passes Industrial, Fails Home Compost Testing

What happened:

A brand wanted OK Compost HOME for dog waste bags.

Material biodegraded at high temperatures, but at 20–30°C (home compost), it degraded far too slowly.

Why it failed:

PLA and many PBAT-heavy blends require high heat → not suitable for Home.

How to avoid it:

- Use compostable materials with PHA or starch blends designed for low-temperature breakdown.

- Perform internal pilot tests at 25°C before applying.

- Avoid thick films — Home compost requires significantly thinner structures.

Key takeaway:

OK Compost HOME is much harder to obtain than Industrial.

Scenario 7 — Non-Compostable Labels or Stickers Cause Failure

What happened:

A compostable produce bag passed testing, but the printed label applied to the final product did not.

Why it failed:

Labels sometimes use non-compostable adhesives or films.

How to avoid it:

- Ensure labels, adhesives, and inks are all certified compostable.

- Request supplier documentation for label components.

- Avoid glossy barriers or laminated labels.

FAQ

What does the OK Compost logo mean?

The OK Compost logo means the product has been tested and certified by TÜV Austria for compostability under specific conditions.

There are two main marks:

- OK Compost INDUSTRIAL: certified for industrial composting facilities (high-temperature composting).

- OK Compost HOME: certified for home composting at lower temperatures (backyard compost).

The logo is not just a marketing claim. It should always be supported by a valid certificate number and scope.

How do I verify an OK Compost certificate number?

To verify an OK Compost certificate:

- Ask the supplier for the certificate PDF (it must show the certificate number, product scope, holder name, and validity).

- Check the certificate number in TÜV Austria’s online database.

- Confirm the certificate is for the finished product, not only for the resin or raw material.

- Make sure the certificate scope matches what you buy (thickness, structure, inks, and product type).

If a supplier only shows the logo but cannot provide a verifiable certificate, treat it as a red flag.

Is OK Compost INDUSTRIAL the same as EN 13432?

Not exactly.

- EN 13432 is a European standard that defines the test requirements for industrial compostability of packaging.

- OK Compost INDUSTRIAL is a certification mark issued by TÜV Austria, based on testing aligned with industrial composting requirements (often linked to EN 13432 compliance for packaging).

In simple terms: EN 13432 is the standard; OK Compost is the recognizable certification label that helps buyers and auditors verify compliance more easily.

Does OK Compost INDUSTRIAL mean home compostable?

No. OK Compost INDUSTRIAL does not guarantee home compostability. Home composting runs at lower temperatures and is less controlled, so materials that pass industrial composting may still break down too slowly at home.

If you need backyard or home composting claims, look for OK Compost HOME (or an equivalent home compost certification in the target market).

Is OK Compost HOME the same as home compostable?

OK Compost HOME is a recognized certification mark for home composting conditions.

It indicates the product is designed to break down in lower-temperature, less controlled composting environments compared with industrial composting.”

What is OK Compost HOME (OKH) and why is it harder?

OK Compost HOME (often abbreviated as OKH) is TÜV Austria’s certification for products that can compost in home compost conditions (lower temperatures, slower biological activity).

It is harder because:

- Home composting is typically 20–30°C, not 55–60°C like industrial composting.

- Many compostable materials (especially thicker films or PLA-heavy structures) may not disintegrate fast enough at low temperatures.

- HOME testing and acceptance criteria are more demanding, and failures often require retesting.

As a practical rule: HOME certification usually requires thinner, simpler structures and carefully selected resin grades.

Do compostable bags need OK Compost to be sold in the EU?

Not always. In the EU, compostability claims for packaging are typically linked to EN 13432 requirements, and brands may use different forms of supporting evidence.

However, OK Compost certification is widely recognized by retailers and buyers and can help with compliance documentation and audit acceptance.”

How do I check if a product is certified?

Search the certificate number in the TÜV Austria database and confirm the certificate is valid, issued to the correct holder, and covers the finished product type and specification you are purchasing.

Does OK Compost guarantee no microplastics?

OK Compost certification requires the product to meet strict compostability criteria, including biodegradation and disintegration, so that it breaks down appropriately in the intended composting environment. Always follow the certification scope (HOME vs INDUSTRIAL) and local composting acceptance rules.

Can OK Compost items go in my green bin?

Only if your local waste program accepts certified compostable packaging in the green bin.

Rules vary by municipality and composting facility, and some programs may accept only specific certified items or none at all.

Resin certified vs product certified: what’s the difference?

Resin certified means the raw material (pellets) may be certified. Product certified means the finished item (the bag you buy) has been tested and certified as a complete structure.

A finished bag can fail even when the resin is certified because real products include thickness changes, printing inks and pigments, additives or coatings, adhesives or seal strips, and multi-layer structures.

For procurement and compliance, always ask for product-level certification that matches the exact bag specification.

Conclusion

OK Compost Certification is more than a label. It is a clear, trusted way to show that a product will break down in the right composting system without harming soil, plants, or the environment.

For brands and buyers, it brings transparency.

For distributors, it reduces risk.

For composting programs, it helps keep contamination low.

If you need OK Compost certified bags or want to understand how this certification affects your packaging plans, you’re welcome to contact us for more details and documentation.