Compostable Garment Bags for USA

Certified compostable garment bags designed for apparel brands, fulfillment centers, and packaging distributors in the United States.

Supplied exclusively for professional B2B apparel packaging programs.

Made from PLA & PBAT compostable materials. No conventional poly plastics used.

Compostable Garment Bags Supplied for the U.S. Market

Compostable garment bags for the United States are widely used by apparel brands, packaging distributors, and fulfillment operations seeking alternatives to conventional plastic apparel polybags.

These compostable garment bags are supplied exclusively for B2B apparel packaging programs, including fashion brands, eCommerce fulfillment centers, 3PL warehouses, and private label distribution models. They are not intended for individual consumer retail sales.

In the U.S. market, compostable garment bags are typically integrated into standard apparel packaging workflows, supporting garment protection, handling, storage, and presentation before shipping.

What Are Compostable Garment Bags in the USA Market?

In the U.S. apparel industry, compostable garment bags—also referred to as compostable apparel polybags or compostable garment polybags—are used as inner packaging for clothing and soft goods.

They are designed to replace traditional LDPE or OPP apparel bags in professional packaging systems, while aligning with compostability expectations under industrial composting conditions.

Our compostable garment bags are manufactured from certified compostable PLA and PBAT materials and do not contain conventional polyethylene (poly). They are distinct from products labeled only as “biodegradable,” which may not meet recognized compostability standards referenced in the United States.

Designed for Apparel Protection, Not for Shipping

Compostable garment bags are designed for apparel protection, not for external shipping or courier use.

These bags are intended to:

- Protect garments from dust and light moisture during handling and storage

- Support folding, sorting, and presentation of apparel items

- Be used as inner packaging within fulfillment and warehouse systems

They are not designed to function as mailer bags and should not be used for heavy items, sharp products, or standalone shipping without an outer mailer.

This clear usage boundary helps ensure consistent performance and reduces the risk of misapplication in apparel packaging programs.

Typical Applications in the U.S. Apparel & Fulfillment Sector

Compostable garment bags for USA programs are commonly used in:

- Apparel brands and fashion labels

- DTC and eCommerce fulfillment centers

- 3PL and warehouse operations

- Private label apparel packaging programs

- Packaging distributors serving apparel clients

In these environments, compostable apparel bags support efficient handling, storage, and presentation of garments prior to shipment.

Compostability Standards & Compliance Considerations in the U.S.

In the United States, compostable garment bags are typically evaluated against industrial composting standards, most commonly ASTM D6400, with many buyers also referencing BPI-recognized compostability.

Important compliance considerations include:

- Compostable garment bags are intended for industrial composting systems, not home composting

- Acceptance may vary by region, facility, and local policy

- Compostability claims and labeling must align with actual processing conditions

Clear and accurate positioning of compostability claims helps U.S. buyers manage regulatory, sustainability, and communication risks.

Performance Requirements for Apparel Packaging

Performance expectations for compostable garment bags differ from those of shipping or courier packaging.

Typical requirements include:

- Suitable strength for soft goods such as apparel and textiles

- Dust protection and basic moisture resistance (not waterproof)

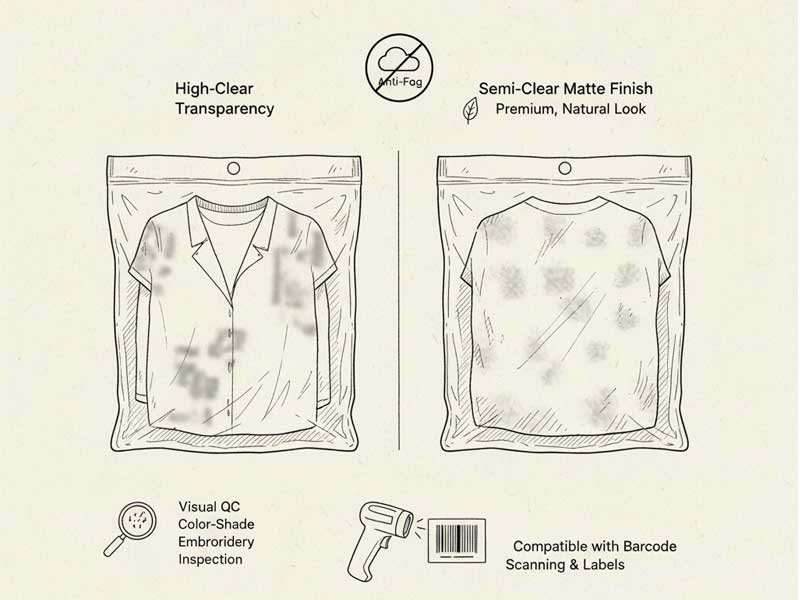

- Stable thickness and transparency for product presentation

- Compatibility with standard apparel packing and folding workflows

These compostable apparel polybags are designed to perform reliably within their intended scope of use.

Resealable & Fulfillment-Oriented Design Options

For U.S. apparel and fulfillment programs, compostable garment bags may be supplied with features that support operational efficiency, including:

- Self-adhesive closures

- Resealable or return-strip options

- Easy-open designs compatible with warehouse handling

- Options suitable for private label packaging programs

These features help integrate compostable garment bags into existing fulfillment systems without disrupting workflow efficiency.

Shelf Life & Storage Guidance for Apparel Programs

Shelf life and storage conditions are important considerations for bulk B2B sourcing.

Typical guidance includes:

- Recommended shelf life of approximately 9–12 months

- Storage in a cool, dry environment, away from heat and direct sunlight

- Use of FIFO (first-in, first-out) inventory management

Proper storage helps maintain bag flexibility, sealing performance, and overall usability throughout the supply cycle.

Quality Consistency for Apparel & Distributor Programs

U.S. buyers often source compostable garment bags as part of ongoing apparel packaging programs, rather than one-time purchases.

Quality consistency is therefore essential, including:

- Stable thickness and bag dimensions across batches

- Consistent sealing and closure performance

- Uniform appearance and transparency

- Reliable repeatability for long-term supply

Consistent production supports predictable performance across fulfillment and retail operations.

Supply Model for the USA Market

Compostable garment bags for the USA are supplied through B2B bulk and program-based sourcing models.

Typical supply characteristics include:

- Bulk supply for apparel brands and distributors

- OEM and private label garment packaging options

- Long-term sourcing partnerships with repeat ordering

- Scalable production to support growing apparel programs

This model allows U.S. buyers to integrate compostable garment bags into standardized apparel packaging systems with stable quality and predictable supply.

Why Choose ORIZON as Your Compostable Garment Bag Manufacturer?

For U.S. B2B buyers, selecting a compostable garment bag supplier involves more than material claims. It requires manufacturing reliability, compliance awareness, and long-term supply stability.

ORIZON supports compostable garment bag programs for the USA market through factory-managed B2B production, designed to meet the operational needs of apparel brands, fulfillment centers, and packaging distributors.

Manufacturing Capabilities Aligned with Apparel Programs

- Consistent production for repeat orders

- Quality control focused on apparel packaging use

- Support for OEM and private label programs

Compliance-Aware Manufacturing for the U.S. Market

- Production aligned with ASTM D6400 industrial composting requirements

- Experience supporting buyers referencing BPI-recognized compostability

- Clear material and usage positioning to reduce compliance ambiguity

Long-Term Supply Partner for USA Apparel Programs

- Program-based sourcing and repeat supply

- Scalable manufacturing for growing brands

- Stable planning for U.S.-bound packaging programs

FAQ – Compostable Garment Bags for USA

No. These bags are designed as inner apparel packaging and should be used with outer mailers for shipping.

Yes. Self-adhesive and resealable options are available for fulfillment-friendly use.

ASTM D6400 and BPI-recognized compostability are commonly referenced.

Acceptance depends on local industrial composting facilities and municipal policies.

They are supplied in bulk through B2B sourcing models, including OEM and private label programs.

Discuss U.S. B2B Apparel Packaging Requirements

If you are sourcing compostable garment bags for the USA market as part of an apparel, fulfillment, or distribution program, bulk supply and project-based sourcing options are available.