Green and environmentally friendly practices have become a global business necessity! In 2024, the global compostable packaging market grew by 18.7% year-on-year, with China becoming a core production base for compostable bags thanks to its complete industrial chain. If you’re looking for reliable Compostable Bag Manufacturers in China, wanting to avoid quality pitfalls and compliance issues while balancing cost and environmental responsibility,

This guide is tailor-made for you! From core standards for manufacturer selection to product certification details, from customization processes to procurement pitfall avoidance techniques, we use 16 years of experience in the biodegradable and compostable industry to help you clarify all key issues, making your green procurement journey smoother, more efficient, and worry-free.

The article is quite long, please read it patiently.

Why Choose Chinese Compostable Bag Manufacturers?

1.A Complete Industrial Chain

Covering the entire product lifecycle: from key raw material supply to molding production, automated packaging, and one-stop

Core raw materials include corn starch and PLA (polylactic acid). This closed-loop industrial layout eliminates intermediate coordination costs and mitigates potential supply chain risks.

2.Strong Economies of Scale

Large-scale production capacity significantly reduces unit production costs. Chinese suppliers offer more competitive prices than European and American manufacturers, and their quality fully meets international standards, providing cost-effective options for bulk purchasing.

3.Technological Iteration and Adaptation to International Environmental Standards

We closely monitor the latest international environmental standards (e.g., EN13432, ASTM D6400, GB/T 38082)

We continuously improve material formulations (e.g., optimization of PLA-starch composite materials) and upgrade advanced production processes (e.g., precision blow molding, environmentally friendly printing) to meet ever-changing market demands.

4.Flexible Production Capacity to Meet Diverse Needs

We offer highly flexible production capacity to meet both small-batch customization (low MOQ) and large-volume purchasing needs. Product specifications, dimensions, and packaging can be customized to meet the diverse needs of different business scenarios.

5.Extensive Export Experience and Compliance

Possessing extensive experience in cross-border trade, with expertise in the certification requirements and regulatory frameworks of major global markets (EU, US, Southeast Asia, etc.). Providing full compliance support, including certification documents, customs clearance materials, and market-specific labeling, ensuring smooth cross-border transactions.

Main Product Matrix of Chinese Compostable Bag Manufacturers (Classified by Procurement Scenarios)

| Procurement Scenario | Product Name | Key Parameters | Suitable Industries/Uses |

|---|---|---|---|

| Food Packaging Scenarios | Compostable Food Bags/Fresh-Keeping Bags | Thickness: 15-30μm (micrometers), Load Capacity: 3-5kg, FDA food-grade certification included | Supermarkets, catering industry; suitable for storing fruits, bread, cooked food, etc. |

| Food Packaging Scenarios | Compostable Takeaway Bags | Leak-proof, Heat-resistant up to 60℃, Load Capacity: 5-10kg, Supports brand LOGO printing | Catering industry (chain milk tea shops, food delivery merchants); meets environmental policy requirements |

| Daily Consumption Scenarios | Compostable Shopping Bags/Tote Bags | Thickness: 20-30μm, Load Capacity: 5-8kg, Perforated design for easy tearing | Supermarkets, brand stores; used for shopping, brand promotion |

| Daily Consumption Scenarios | Compostable Trash Bags | Household size: 10-20L, Commercial size: 50-100L, Decomposition cycle: 6-12 months | Households, canteens, office buildings; compatible with waste sorting requirements |

| Logistics Packaging Scenarios | Compostable Courier Bags | Material: Waterproof PE lamination + PLA, Load Capacity: 8-15kg, Supports direct shipping label printing | Cross-border e-commerce, domestic e-commerce; replaces traditional plastic courier bags |

| Logistics Packaging Scenarios | Compostable Cushioning Packaging | Honeycomb structure, Shock-proof and pressure-resistant | E-commerce industry; suitable for packaging fragile items like ceramics, glass |

| Special Industry Scenarios | Compostable Pet Waste Bags | Portable individual packaging, Strong sealing, Complies with EU/US environmental standards | Cross-border pet product industry; suitable for collecting pet waste during walks |

| Special Industry Scenarios | Compostable Gardening Bags | Breathable and water-permeable, Converts to organic fertilizer after decomposition | Gardening industry (flower shops, planting bases); suitable for growing succulents, pothos, etc. |

2025 Top Compostable Bag Manufacturers in China (Branch-Specific Sector)

Choosing the right manufacturer depends entirely on your specific needs—whether you’re exporting globally, needing custom designs, ordering in bulk, or targeting niche scenarios. I’ve sorted through industry data and buyer feedback to recommend top players in each segment, with practical details you can act on.

Export-Oriented Manufacturers:

Shandong Orizon Biomaterials Co., Ltd

- Core Advantages: 16+ years of export experience, integrated supply chain from self-developed modified resin to finished bags, and stable raw material supply from Shandong’s agricultural cluster . No delays from global material shortages.export experience, integrated supply chain from self-developed modified resin to finished bags, and stable raw material supply from Shandong’s agricultural cluster

- Main Products: Compostable garbage bags, supermarket shopping bags, fruit and vegetable bags, and pet waste bags, all made from corn starch, PBAT, and PLA.

- Cooperation Client Types: Cross-border e-commerce sellers, overseas supermarkets, and pet product brands in Europe, America, and Oceania .

- Certification Qualifications: EU EN13432, US ASTM D6400 (Our company’s identification number can be found on the BPI website: 10529118 ), and Australian AS4736—covers all major global markets .

Zhuhai UNNI Biotech Co., Ltd.

- Core Advantages: 10 automatic production lines, 99.1% on-time delivery rate for export orders, and multilingual customer service . Proficient in customs clearance for EU and US markets.export orders, and multilingual customer service . Proficient in cust

- Flagship Products: Compostable food bags, trash bags, and mailing bags with annual output of 8000 tons (about 10 billion pieces) .

- Cooperation Client Types: International retailers, cross-border brands, and eco-friendly product distributors .

- Certification Qualifications: TUV (EU) and BPI (US) certifications, meeting the strictest global biodegradability requirements .

Dongguan Sentor Plastics Products Co., Ltd.

- Core Advantages: Located in Guangdong’s export hub, 12 years of cross-border experience, and 2-hour average response time for inquiries . Fast logistics access to major ports.

- Flagship Products: Pet waste disposal bags, compostable plastic bags, and custom-printed export-grade bags .

- Cooperation Client Types: Small-to-medium cross-border sellers and overseas pet product brands .

- Certification Qualifications: EN13432 and ASTM D6400 certified, with clear compliance documentation for customs .

Custom Service-Oriented Manufacturers

These factories excel at turning your unique needs into reality, even for small batches.

Torise Biomaterials (Henan)

- Personalized Solutions: Full customization of size, color, thickness, and logo printing. Can develop specialized bags for unique scenarios—like matte-finish skincare packaging or leak-proof meal prep bags .

- Minimum Order Quantity (MOQ): As low as 5000 units for standard designs; 5000 units for complex customizations .custom

- Design Support Capabilities: In-house design team provides 2D/3D mockups within 24 hours. Offers material advice to balance functionality and cost .

Dongguan Min Lee Packaging Material Co., Ltd.

- Personalized Solutions: Customizable bag structures (zippered, stand-up, perforated), eco-friendly ink options, and branding integration . Specializes in matching brand color palettes.

- Minimum Order Quantity (MOQ): 5000 units for most products, with flexible terms for repeat clients .

- Design Support Capabilities: 5.0/5.0 client rating for design communication. Provides physical samples within 7 days of finalizing designs .

Shandong Orizon Biomaterials Co., Ltd.

- Personalized Solutions: Tailors material blends (PLA/PBAT ratio) for specific uses—like thicker bags for heavy items or thinner ones for light products .

- Minimum Order Quantity (MOQ): 5000 units, ideal for startups and niche brands .

- Design Support Capabilities: Works with you to optimize designs for cost and sustainability. Shares test reports for custom materials .

Large-Batch Supply-Oriented Manufacturers

When you need massive quantities at competitive prices, these factories deliver stability and scale.

Shenyang Zhonghe Plastic Packaging Co., Ltd.

- Production Capacity: 5000 tons annual output after 2024 intelligent upgrade—enough for 100 million+ bags yearly .

- Delivery Cycle: 15-20 days for bulk orders, with 98% on-time delivery rate .

- Price Advantage: 30-40% lower than small-scale factories, thanks to automated production and bulk raw material sourcing .factories,

- Cooperation Model: Long-term supply agreements with price locking. Provides inventory management support for large retailers .

Techuang Biology (Zhejiang)

- Production Capacity: 120,000 tons annual capacity (Phase 1), with Phase 2 expansion underway . Can handle orders of 500,000+ units easily.

- Delivery Cycle: 12-18 days for bulk orders. Has backup production lines to avoid delays .bulk orders

- Price Advantage: Economies of scale from integrated production (granulation to bag-making) .

- Cooperation Model: OEM/ODM partnerships with major brands. Offers free sample testing for long-term contracts .

Torise Biomaterials (Henan)

- Production Capacity: 30,000 tons annual bag output, supported by 200,000 tons/year resin production .

- Delivery Cycle: 18-25 days for full-capacity orders .

- Price Advantage: Vertical integration (resin to finished product) cuts intermediate costs .

- Cooperation Model: Bulk pricing tiers. Provides logistics optimization for large shipments .

Niche Scenario Experts

These manufacturers focus on specific fields, mastering the unique requirements of each.

Food Packaging Specialists

Shenyang Zhonghe Plastic Packaging Co., Ltd.

- Core Competitiveness: Food-grade production workshops with disinfection processes. Bags are heat-resistant (up to 60℃) and leak-proof .

- Key Strengths: Serves Xijiade (hot pot chain) and Shuanghui Group (food giant), understanding food safety and shelf-life needs . ISO9000 certified with full traceability .

Shandong Xingyuan Zhicheng

- Core Competitiveness: FDA food-grade certification. Specializes in fresh-keeping bags with optimized thickness (15-30μm) to balance freshness and degradation .

- Key Strengths: Raw material control ensures no harmful migration—safe for direct food contact .

Logistics Packaging Specialists

Techuang Biology

- Core Competitiveness: Focus on compostable courier bags and cushioning materials. Bags use waterproof PE lamination + PLA for durability .

- Key Strengths: Core supplier to China Post and SF Express. Bags withstand sorting and transportation without tearing . Honeycomb cushioning reduces fragile item breakage .supplier to China Post and SF Express. Bags withstand sorting and transportati

Special Scenario Experts

Pet Waste Bag Specialist: Dongguan Sentor Plastics

- Core Competitiveness: Portable individual packaging, strong sealing, and EN13432 certification . Bags trap odors effectively.

- Key Strengths: Popular with cross-border pet brands—fits global eco-friendly pet product standards .

Gardening Bag Specialist: Shandong Aisun ECO Materials Co., Ltd.

- Core Competitiveness: Breathable, water-permeable design. Degrades into organic fertilizer in 6-12 months .

- Key Strengths: Thickness optimized for plant growth—supports root respiration while preventing soil leakage .

Compostable Bag Terminology (Essential for Procurement)

Compostable vs. Biodegradable

This is the most crucial difference, and also the easiest concept to be misunderstood.

“Biodegradable” is a broad term; any plastic that can break down into small pieces or be decomposed by microorganisms can be called “biodegradable.” However, some biodegradable bags leave behind microplastics after decomposition, still polluting the environment.

Compostable is the “advanced” version of biodegradable, with specific standards and requirements. It must completely decompose into water, carbon dioxide, and organic fertilizer under specific conditions, leaving no harmful residues. Simply put, compostable is always biodegradable, but biodegradable is not necessarily compostable.

I had a client who mistakenly exported “biodegradable bags” as “compostable bags” to Europe. As a result, the entire shipment was returned because the degradation products did not meet standards, resulting in a loss of hundreds of thousands of dollars.

Industrial Composting vs. Home Composting

These two types of composting have completely different product standards; choosing the wrong one will render the product unusable.

- Industrial composting requires the environment of a professional composting plant—a temperature maintained above 55℃, along with specific humidity and microbial conditions. Most commercial compostable bags (such as supermarket shopping bags and courier bags) meet industrial composting standards and cannot decompose in ordinary home environments.

- Home compostable bags, on the other hand, can naturally degrade in balcony compost bins or garden soil without special conditions, typically taking 6-12 months to decompose. They are suitable for home users and small-scale gardening.

Before purchasing, be sure to clarify: Is your product for home use or intended for industrial composting? Don’t buy the wrong standard.

PLA Material vs. Corn Starch Material

These are the two most commonly used core materials for compostable bags, with significant differences in properties and suitable applications.

- PLA (polylactic acid) is extracted from plants such as corn and sugarcane. It has stronger heat resistance, able to withstand temperatures from -10℃ to 60℃, and is less prone to deformation and leakage. It is suitable for food bags, takeout packaging bags, and courier bags—products requiring a certain load-bearing capacity and temperature resistance.

- The advantage of cornstarch-based materials is their rapid degradation, typically breaking down completely in 6-8 months. However, they have poor heat resistance, softening easily above 40℃. This makes them more suitable for products like garbage bags and garden bags, where temperature resistance requirements are not high.

When helping restaurant clients choose bags, I always prioritize PLA-based takeout bags because they don’t deform when holding hot food; while for household garbage bags, cornstarch-based materials offer better value for money.

Basic Procurement Indicators

If the concept is the “bottom line for avoiding pitfalls,” then these parameters are the “key to choosing the right product.” Each parameter should be clearly provided by the manufacturer, ideally included in the contract.

Degradation Rate

This is the core indicator for compostable bags, without exception.

According to the internationally accepted standard (EN13432), compostable bags must achieve a degradation rate of 90% or higher within 180 days. Failure to meet this standard renders the product unqualified for composting, posing compliance risks for export or sale.

When purchasing, always request testing reports from authoritative institutions such as SGS and TUV, focusing on the “180-day biodegradation rate.” A rate below 90% is immediately rejected.

Bio-based

Bio-based content refers to the percentage of plant-derived components in the bag. Higher content indicates greater environmental friendliness and is a compliance requirement in many markets.

Especially for food-grade compostable bags, according to the Chinese national standard GB/T 38082-2019, the bio-based content must be ≥40%. European and American markets also have clear regulations on bio-based content; levels below the standard will affect customs clearance.

This parameter reflects the quality of the manufacturer’s raw materials. Bags with high bio-based content offer better environmental protection and safety.

Load-bearing capacity

Load-bearing capacity directly affects the usability of the product; nobody wants to buy a bag that breaks easily.

Different scenarios require different load-bearing capacities: regular shopping bags ≥ 5kg (can hold 5 bottles of 500ml water), courier bags ≥ 8kg (can withstand the wear and tear of sorting and handling).

Another crucial indicator is “seam strength ≥ 15N/15mm”—the seams are the most vulnerable points to breakage. This parameter ensures strong seams that are not easily cracked. When purchasing, you can ask the manufacturer to provide seam strength test data, or you can test samples yourself.

Temperature resistance

Temperature resistance determines the bag’s intended use, especially for food contact products, which must be carefully considered.

Food contact compostable bags (such as freezer bags and takeout bags) must withstand temperatures ranging from -10℃ to 60℃: they must not crack at low temperatures (suitable for refrigerated foods) and must not deform at high temperatures (suitable for hot foods).

For ordinary garbage bags and garden bags, the temperature resistance requirements are not as stringent, but it is still essential to confirm the manufacturer’s temperature resistance parameters to avoid problems during use.

Heavy Metal Residue

This is a critical safety indicator, especially for food contact compostable bags, and cannot be ignored.

Residues of heavy metals such as lead, mercury, and cadmium must comply with Chinese GB/T 38082-2019 and US FDA standards. Excessive heavy metal levels can harm health through food contact and soil degradation. If detected, the product will be recalled and may face fines.

When purchasing, always request a heavy metal testing report from the manufacturer to confirm that all indicators are within the limits. This step is crucial.

2025 Six Standards for Compliant Chinese Compostable Bag Manufacturers

When purchasing compostable bags, choosing the right manufacturer is more crucial than choosing the right product. I’ve seen too many buyers fall into the trap of fake certifications, or suffer from delivery delays and reduced quality, because they didn’t understand the selection process.

These 8 core standards are a “pitfall avoidance guide” I’ve compiled based on 10 years of industry experience—each with a directly applicable verification method to help you accurately identify reliable manufacturers.

Compliance and Qualification Requirements

Compliance is a prerequisite for cooperation. Without proper qualifications, all further discussions are meaningless.

- International Certification Validity (Dual Certification is a Hard Indicator)

Reliable manufacturers must possess both EN13432 (EU Standard) and ASTM D6400 (US Standard) dual certifications – this is the “passport” for products to enter mainstream global markets.

Three-step verification method to avoid “certificate fraud”:

- ① Obtain the complete certification certificate from the manufacturer, noting the certificate number and certification body (e.g., TUV, SGS, BPI);

- ② Log in to the corresponding certification body’s website and find the “Certificate Inquiry” entry;

- ③ Enter the certificate number and verify that the manufacturer’s name and product model on the certificate completely match the product you are purchasing.

Last year, when I was verifying for a European client, I discovered that a manufacturer’s certificate number corresponded to “biodegradable garbage bags,” not the “food-grade compostable bags” the client requested – this is a typical case of “certificate fraud,” and it was immediately rejected.

- Complete Production Qualifications (Dual Guarantee of Safety and Compliance)

- Basic Requirements: A “Production Environmental Protection License” must be provided, proving that the factory’s emissions meet standards and will not be shut down due to environmental issues.

- Additional Requirements for Food-Grade Products: SC certification (Food Contact Packaging Production Qualification) is required; this is the minimum requirement for bags to directly contact food.

- Verification Method: Obtain a copy of the manufacturer’s qualification certificate. Log in to the official website of the State Administration for Market Regulation of China, and in the “Food Production License Information Inquiry” or “Industrial Product Production License Inquiry” section, enter the manufacturer’s name and qualification number to verify the validity period (generally 3-5 years). Expired qualifications are considered invalid.

- Industry Authority Endorsement (Preferred Choice)

If the manufacturer is a member of the International Association for Composting (IAA) or a council member of the Environmental Packaging Professional Committee of the China Packaging Federation, the cooperation risk will be lower.

These associations have strict review processes for their members; membership signifies that the manufacturer’s production scale, technical level, and compliance have been recognized by a third party.

Verification method: Ask the manufacturer to provide a membership certificate, or check the membership list on the association’s official website to confirm that the manufacturer’s name is listed.

Quality Assurance

Qualifications are just the facade; quality is the core. These two points directly relate to whether the product is usable and compliant.

- Traceable Test Reports (Valid Only Within the Last 6 Months)

Manufacturers must provide test reports issued by authoritative third-party organizations such as SGS and TUV, and the report date must be within the last 6 months—reports older than 1 year may have outdated parameters.

Three key indicators to check:

- Degradation Rate: ≥90% (compliant with EN13432/ASTM D6400 standards); Heavy Metal Residue: Lead, mercury, etc., must comply with GB/T 38082-2019 and FDA standards; Bio-based Content: ≥40% for food-grade products.

- Verification Method: Request a test report with a QR code from the manufacturer. Scanning the QR code will redirect to the testing agency’s website to verify the report’s authenticity, preventing “forged reports.”

- Production Process Compliance (Environmentally Friendly + Highly Efficient)

Don’t just look at product samples; the factory’s production process directly affects the stability of bulk product quality.

Verification Method: Request factory videos or conduct video verification. Focus on two key points:

- ① Core Equipment: Are the blown film machine and printing machine environmentally friendly (with waste gas treatment devices and water recycling systems)? Avoid products with uneven thickness and blurry printing due to outdated equipment;

- ② Production Environment: Is the workshop clean and well-organized (raw material area, production area, finished product area)? Poor hygiene in factories can easily lead to bacterial growth in food-grade products.

Cooperation Capability

Even if qualifications and quality meet standards, it’s still important to assess the manufacturer’s ability to “cooperate effectively”—after all, delivery delays and customization issues will impact your business progress.

- Production Capacity and Delivery Cycle

- Standard Requirements: Obtain the manufacturer’s maximum production capacity per batch (e.g., “1 million units per batch”). The standard order delivery cycle should be controlled within 7-15 days.

- For Expedited Requests: Confirm whether 3-5 day expedited production is supported, and the surcharge for expedited orders (generally 10%-20% higher than the standard price).

Verification Method: Obtain the manufacturer’s production order records for the past 3 months (customer information redacted), or provide case studies of major clients to determine if their production capacity matches your order volume. For example, if you need to order 500,000 units per month, but the manufacturer’s single-batch capacity is only 300,000 units, there may be delivery pressure later.

- Customization Service Compatibility

If you need to customize your logo, size, or color, be sure to confirm the manufacturer’s compatibility capabilities beforehand:

- Printing Support: Can they do 1-4 color printing? Can the colors accurately match your brand colors?

- Design Services: Do they offer free logo design? How many revisions are supported?

- Mold Opening Fees: Is mold opening required for special sizes? The fee is generally 500-1000 RMB, negotiable for large orders (e.g., over 100,000 pieces).

Verification Method:

- First, ask the manufacturer to provide a printed sample to confirm that the color and clarity meet the standards;

- when signing the contract, clearly define the customization requirements and costs to avoid hidden price increases later.

Risk Control (Key to Avoiding Pitfalls, Safeguarding the Last Line of Defense)

A good manufacturer will help you mitigate risks in advance; an unreliable manufacturer will only cause trouble afterward.

- After-Sales Guarantee Mechanism

- Sample Testing: Confirm sample policy (free samples + freight collect, or “sample fee refunded after order placement”) to avoid “high sample fees, non-refundable after order placement”;

- Bulk Inspection: Agree on a bulk inspection rate of ≥3%, unconditional return or exchange for unqualified samples;

- Return/Exchange Time Limit: Clarify that the return/exchange time limit for quality issues (such as substandard degradation rate, insufficient load-bearing capacity) is within 7 days. The manufacturer will not be responsible after this time limit.

Cross-Border Service Capabilities

For cross-border procurement, additionally confirm 3 points:

- ① Customs Declaration Documents: Can the manufacturer provide a complete set of customs clearance documents, including commercial invoices, packing lists, and certification copies?

- ② Payment Methods: Does the manufacturer support cross-border payment methods such as letters of credit and PayPal?

- ③ Compliance Consulting: Can the manufacturer provide compliance advice for the target market (e.g., Europe requires an additional “Food Contact Declaration”).

Verification Method: Ask the manufacturer to provide past cross-border order customs declaration cases (sensitive information redacted) to determine their mature cross-border service experience.

Where to Choose a Chinese Compostable Bag Manufacturer

Supply Channels: Online platforms such as Alibaba, Global Sources, and Made-in-China are important starting points for finding manufacturers. These platforms not only provide extensive supplier information but also offer product details, certifications, and buyer reviews.

Search engines can broaden your search potential, especially by using precise keywords combined with your purchasing needs to identify specialized manufacturers in a specific niche.

Industry exhibitions such as the China International Plastics and Rubber Industry Exhibition and the Green Packaging Expo are also excellent venues for sourcing suppliers. These exhibitions allow buyers to meet face-to-face and gain a deeper understanding of companies’ strengths and latest technologies.

Third-party sourcing agents: Useful for audits and negotiation, but ensure transparency in fees.

Referrals and industry networks: A strong way to identify vetted manufacturers already working with retailers or e-commerce brands.

Compostability Certification Standards

A trustworthy compostable bag supplier should hold valid certifications. Always confirm them in official databases, not just scanned PDF copies.

- EN 13432 (EU) – The European standard for industrial compostability. Required by EU regulators. EU Commission reference.

- ASTM D6400 (U.S.) – Standard for compostable plastics, often certified by BPI (Biodegradable Products Institute). Buyers can search the BPI Certificate Directory to verify validity.

- AS4736 & AS5810 (Australia) – For industrial and home compostability, recognized by the Australian government.

- OK Compost & OK Compost HOME (TÜV Austria) – Internationally recognized eco-labels. Publicly searchable TÜV database.

As far as I know, these are internationally authoritative third-party organizations that ensure that products meet the requirements of biodegradability and non-toxicity under controlled conditions. They are key references for identifying product authenticity and environmental friendliness.

Assess Quality Control and Manufacturing Capacity

- Production capacity: Confirm monthly tonnage and lead times. For large retailers, ensure at least 10–20 container loads per year capability.

- Factory audits: Request on-site or virtual audits to confirm equipment, capacity, and compliance with ISO 9001 quality systems.

- Sample testing: Test tensile strength, leak resistance, and shelf-life stability in your own lab or through SGS / Intertek.

- Batch testing: Require random third-party inspections before shipment.

10-Step Hands-on Process in Collaboration with Compost Bag Manufacturers China

The success of a collaboration hinges entirely on process control. Having helped buyers connect with compostable bag manufacturers, I’ve summarized this 10-step practical process—each step contains details to avoid pitfalls. Following these steps will ensure a worry-free experience from initial requirements to after-sales service.

- Clearly Define Requirements:

Before collaborating, thoroughly clarify your requirements to avoid repeated modifications and wasted time later.

Key points to clarify include: Product type (e.g., food bags/courier bags), dimensions (length × width × thickness, thickness specified in μm), load-bearing capacity (e.g., 5kg/8kg), printing requirements (1-4 colors, logo source file, printing location), order quantity (initial order + subsequent replenishment), delivery time (including buffer period), target market (determine compliance standards, e.g., EN13432 for Europe), and special requirements (e.g., leak-proof, matte material).

For example: “Purchase compostable takeout packaging bags, dimensions 25cm×35cm×10cm, thickness 25μm, load capacity 8kg, 2-color logo printing (AI file provided), initial order 50,000 bags, delivery within 30 days, target market EU (EN13432 certification required), leak-proof design required.”

- Manufacturer Screening: Screen 3-5 candidates through 3 channels

Don’t rely on just one channel to find manufacturers; multi-dimensional screening increases reliability.

B2B platforms (e.g., Alibaba): Search using keywords like “compostable bags + EN13432 + ASTM D6400,” prioritizing “gold suppliers” and “on-site certified factories,” excluding those without certification or with poor reviews;

Industry exhibitions (e.g., China Packaging Industry Exhibition): Offline, you can directly view samples, discuss production capacity, and verify qualifications on-site, suitable for finding leading manufacturers;

Reputation recommendations: Ask peers or cross-border logistics providers; manufacturers they have worked with are more valuable references, helping you avoid known pitfalls.

Final selection: narrow down to 3-5 companies. Too many will be overwhelming, too few will limit comparison.

- Initial Contact: Send

Send the compiled requirements list to the candidate manufacturers, focusing on four key questions: pricing, MOQ, customization cycle, and whether they have certifications relevant to the target market.

Quickly eliminate two types of manufacturers: those whose prices are 20% higher than the industry average (without a reasonable explanation) – pass them immediately; those without certifications for the target market (e.g., targeting the European market but lacking EN13432) – don’t waste time on in-depth communication.

When I previously helped clients, some manufacturers quoted 30% higher than their competitors, citing “better materials,” but couldn’t provide supporting test reports; these were immediately eliminated.

- Sample Request: Free samples + freight collect, tested according to standards

Request free samples from the remaining manufacturers; freight is usually collect (reliable manufacturers won’t ask you to pay for samples in advance). Upon receiving the samples, test each item according to the “Core Parameter Table”:

- Degradability: Refer to the manufacturer’s test report (degradation rate ≥90%). A simple soil burial test can also be performed (observe softening after 2 weeks);

- Load-bearing capacity: Fill with an item of the corresponding weight (e.g., 5kg of water), let stand for 10 minutes, and check for damage or deformation;

- Sealing: Fill with a small amount of water and shake to test for leakage (for takeout bags and food bags);

- Printing effect: Check the logo color and clarity for any smudging or misalignment.

Manufacturers failing the tests will be removed from the candidate list.

- Qualification Verification:

This is the most crucial step. Don’t just look at the pictures provided by the manufacturer; verify their authenticity item by item.

Request the manufacturer to provide three types of documents: EN13432/ASTM D6400 dual certification certificates, SGS/TUV test reports from the last 6 months, and an environmental production license (for food-grade products, add SC certification).

Follow the previously mentioned “verification method”: Check the certification number on the official website, verify the test report by scanning the QR code, and check the production qualification’s validity period on the State Administration for Market Regulation’s website. If any verification fails, abandon the project immediately.

- On-site Inspection (essential for large orders):

If the order quantity exceeds 50,000 units, or the annual purchase amount exceeds 1 million, an on-site factory inspection is essential—pictures and videos can be “beautified,” only seeing it in person provides the truth.

Focus on 3 points:

- Production Environment: Is the workshop clean? Are raw materials and finished products stored separately? Is there environmental protection equipment?

- Equipment Capacity: Measure the quantity and condition of blown film machines and printing machines to determine if they can meet your order volume.

- Case Studies: Ask the manufacturer to show past cooperation contracts with major clients (reduce sensitive information), such as whether they have cooperated with well-known supermarkets and e-commerce platforms, to verify their supply capacity.

I once accompanied a client to inspect a factory. The pictures showed a large factory, but in reality, it only had 2 production lines, and the production capacity was far from sufficient. We immediately ruled it out.

- Contract Signing:

All key terms must be clearly written into the contract, leaving no room for ambiguity.

Core terms include:

- Price: Clearly state the unit price and total price, including whether printing, mold, and logistics costs are included;

- Payment Method: A “30% prepayment + 70% final payment” (final payment upon acceptance of goods) is recommended to avoid full prepayment;

- Delivery Cycle: Clearly state the production date, shipping date, and arrival date, allowing a 7-day buffer period;

- Quality Standards: Clearly state parameters such as degradation rate, load-bearing capacity, and temperature resistance, and attach test reports as appendices;

- Late Delivery Compensation: Agree on a daily penalty of 0.5% (maximum not exceeding 10% of the total contract amount) to incentivize the manufacturer to deliver on time.

- Production Follow-up:

Paying a prepayment does not mean you can rest easy. Proactive follow-up allows for timely identification of problems.

Require the manufacturer to provide production progress updates every 3 days: for example, “Raw materials have arrived at the factory,” “30% of the blown film has been completed,” and “Printing is in progress.”

For critical stages (printing, bag making), manufacturers must provide actual videos or pictures to verify that the printing colors and bag sizes meet requirements. This allows for timely adjustments if problems are found, preventing the entire batch from being incorrect.

- Logistics Coordination:

Choose logistics based on order urgency:

- Sea Freight: Low cost, suitable for non-urgent orders; delivery to Europe and America typically takes 30-45 days.

- Air Freight: The preferred option for expedited orders, delivery takes 3-7 days, but the cost is 3-5 times higher than sea freight.

Have the manufacturer prepare a complete set of customs clearance documents in advance: commercial invoice, packing list, copies of certification certificates, and test reports. Ensure all documents are complete and consistent (e.g., manufacturer name, product model must match the contract).

If you lack customs clearance experience, you can entrust a freight forwarder for a hassle-free and efficient process.

- Acceptance and After-Sales Service:

- After the goods arrive at the port, random inspections will be conducted according to contract standards. Final payment will only be made if the goods pass inspection.

- Sampling inspection rate ≥3%: Randomly select a portion of bags to test load-bearing capacity, sealing performance, and printing quality, and verify quantity consistency. If the sampling inspection fails, returns, exchanges, or claims will be made according to the contract.

- After acceptance, retain the WeChat, phone number, and email address of the after-sales contact person for future replenishment, secondary customization, or handling of quality issues.

I had a customer who paid the final payment without sampling inspection upon delivery, and later discovered that 10% of the bags had printing errors. This put them in a very passive position when seeking redress from the manufacturer—therefore, this sampling inspection step is absolutely essential.

How to Verify Compostable Bag Manufacturers China

Confirming the supplier’s authenticity is paramount. Due to distance, the following methods can be used:

- Video conferencing: This is the most intuitive method. You can ask the supplier to visit the factory directly or provide a complete production video, allowing you to see the office, raw materials, blown film printing, production equipment, workshop workers, and finished product warehouse.

- Official documents: The company’s business license and export license. These demonstrate their legal status and international trade qualifications.

- Website: Check the company’s website to identify their team, international sales team, social media channels, etc.

- Verify certifications directly in official databases such as the BPI Certificate Directory or TÜV Austria OK Compost database. For example, BPI certificates list the manufacturer’s name, product type, and expiration date, allowing buyers to confirm authenticity. In the EU, EN 13432 certification is mandatory for claims of industrial compostability; shipments without this may face fines or seizure under local waste legislation. (You can find our company identification number on the BPI official website: 10529118. )

Is There a Quality Control System?

Almost all suppliers will display certification marks such as BPI, TUV/OK compost on their websites.

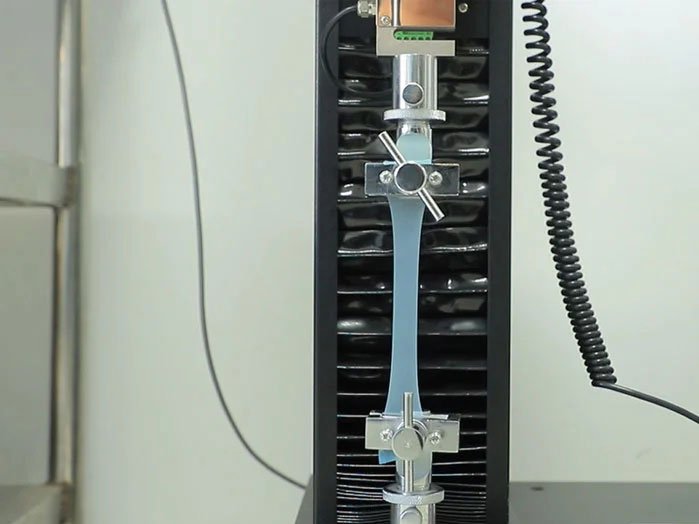

- End-to-End QC Process: Ask about their quality control process. Does it include IQC (incoming raw material inspection), PQC (production process inspection), and FQC (finished product final inspection)? What specialized equipment (such as tensile testing machines and thickness gauges) do they use to ensure product performance?

- Raw Material Traceability: Understand the sources of their raw materials, such as PLA, PBAT, and corn starch.

- Internal Testing Reports: Can you provide batch testing reports for routine production? This ensures that every batch of product complies with the EN13432 standard.

At ORIZON, we not only hold all key international certifications, but more importantly, we provide detailed internal quality inspection reports for every bulk order, covering key indicators such as dimensions, thickness, and load-bearing capacity, ensuring that the products we deliver are flawless.

Professional Service

A good compostable bag manufacturer should be a professional service provider.

How to identify one?

- International Sales Team: Can the contact person communicate fluently in English? Do they understand your market and needs? Can they accurately understand your custom printing and specifications?

- Clear Response Time Commitment: Can they respond to your emails or inquiries within a specified timeframe (e.g., 12 or 24 business hours)?

- Clear Cooperation Process: Can they provide a clear process flow from inquiry, quotation, proofing, production, to delivery? This will give you stable expectations throughout the project.

ORIZON’s international sales team is comprised of experts with over five years of foreign trade experience. We promise to respond to any questions within 12 business hours and provide you with one-on-one follow-up service throughout the project.

Logistics Capabilities to Investigate:

- Extensive Export Experience: Their primary export markets. Having experience serving clients in your country or region is a plus.

- Incoterms: Do they offer options other than FOB (Free on Board)? Especially DDP (Delivery Duty Paid) services can save you time and effort in customs clearance and logistics.

- Professional Packaging and Loading: Learn how to pack and load your goods. Professional palletizing, stretch film protection, and container loading ensure that your goods remain intact during long-distance ocean shipping.

Suggestions for Obtaining Samples and On-site Inspections

After confirming a candidate manufacturer, it’s crucial to obtain product samples. The sample acquisition process should be clearly documented, taking into account shipping costs and quality comparisons. Upon receipt, the samples should be tested for physical properties and compostability to verify their true performance.

When inspecting the factory, focus on ensuring that the production process is standardized, the equipment is advanced and comprehensive, and that an independent laboratory conducts quality inspections. Hygiene and safety management are also crucial.

In addition, observing the supplier’s communication efficiency and customer service attitude can predict the success of future collaborations. Suppliers who are professional, responsive, and cooperative are more trustworthy.

Real-World Collaboration Case Studies and Production Capabilities

- Industry Case Studies: Can you share some anonymous success stories from clients in your industry (e.g., retail, catering, e-commerce)?

- Quantifiable Capacity: Ask for specific capacity figures, including minimum order quantity (MOQ), monthly production capacity (tons), and factory area (square meters).

- Customer Reviews: Authentic customer feedback is a powerful testament to their service quality.

Procurement Contracts and Risk Control

International sourcing involves multiple risks—plan ahead with protective measures.

- Currency risks: Fix exchange rates via forward contracts or negotiate USD pricing.

- Logistics risks: Port delays and customs holds. Use experienced freight forwarders and define Incoterms (FOB, CIF, DDP) in contracts.

- Contract clauses: Include quality standards, delivery deadlines, defect-rate thresholds, and penalties for late shipments.

- Payment security: Prefer letters of credit (LC), escrow, or trade insurance over 100% advance payments.

Risk prevention measures are essential, such as implementing a quality spot check system, paying by batch, and reserving arbitration options for dispute resolution to mitigate procurement risks.

Logistics, Customs Clearance, and Import Regulations

After procurement, the logistics choice directly impacts cost and delivery speed. Depending on the purchase volume and destination, sea, air, or land transport options can be selected, and each method requires a balance between cost and efficiency.

Customs clearance procedures can be complex due to varying regulations in the importing country. Understanding the destination country’s environmental certification and packaging requirements for compostable bags in advance will ensure smooth customs clearance and avoid port detention or fines.

- United States: Compostable bags claiming “biodegradable” must follow FTC Green Guides to avoid greenwashing fines. FDA approval may be required for food-contact bags.

- European Union: EN 13432 certification is mandatory; non-compliant imports can be seized. Labeling must follow EU Packaging Waste Directive.

- Australia: Only AS4736 / AS5810 certified bags may be marketed as compostable. Retailers are fined for mislabeling.

- China export rules: Products must be declared with the correct HS code (392321 or 392329), with matching test reports.

Environmental regulations in importing countries are becoming increasingly stringent. Products that comply with local laws and regulations are more likely to obtain market access certificates and enhance their competitiveness.

Practical Checklist for Buyers

A quick checklist of the sourcing process from a Chinese compostable bag manufacturer:

- Verify EN 13432 / ASTM D6400 / BPI certification numbers in official directories

- Request factory ISO 9001 and production line audit reports

- Test product samples for strength, leakage, and compostability

- Confirm HS codes and import documentation with your customs broker

- Define Incoterms and payment terms clearly in contracts

- Use third-party inspections before shipment release

Conclusion

Identifying and selecting Chinese compostable bag manufacturers not only impacts product quality and supply reliability but also directly influences a company’s environmental image and market competitiveness. In the context of green environmental protection, buyers should carefully select long-term partners, monitor manufacturers’ technological innovations and industry developments, and continuously optimize procurement plans to achieve a win-win, green future.