In fashion retail, packaging details often signal brand positioning before a customer even looks at the product.

Among different carry bag options, die-cut compostable bags have become one of the most common choices for boutique and fashion retailers. They offer a clean appearance, controlled structure, and reliable branding space—while meeting growing sustainability and compliance expectations.

However, sourcing die-cut compostable bags for fashion retail is not just about choosing a shape. Bag size, film thickness, printing feasibility, and certification requirements all affect how well the bag performs in real retail environments.

This article takes a closer look at die cut compostable bags used in fashion retail, focusing on size selection, printing considerations, and compliance requirements from a B2B sourcing perspective.

What Are Die-Cut Compostable Bags?

Die-cut compostable bags are flat carry bags with a punched handle, manufactured from certified compostable materials.

Compared with other carry bag structures, die-cut bags offer:

- A clean, rectangular silhouette

- Better surface consistency for branding

- More predictable strength distribution around the handle area

In fashion retail, they are commonly used as primary takeaway bags, especially in boutiques where appearance and brand presentation matter.

Die-cut structures are most commonly used in boutique environments where appearance, branding, and controlled sizing matter.

For a broader overview of carry bag options used in fashion retail, including when different structures make sense, you can also refer to our guide on compostable boutique bags.

Why Fashion Retailers Prefer Die-Cut Compostable Bags

Clean Appearance and Brand Alignment

Fashion brands often favor packaging that feels minimal and intentional. Die-cut bags align well with this approach because they avoid the visual clutter of side gussets or external handles.

The flat structure also allows logos and brand elements to sit more evenly, which is especially important for monochrome or minimalist brand identities.

Balanced Strength for Apparel Items

Unlike grocery or convenience retail, fashion items typically vary in shape but not extreme weight. Die-cut compostable bags can be specified with sufficient thickness to handle:

- Folded garments

- Light outerwear

- Accessories and boxed items

When specified correctly, they provide a reliable balance between appearance and load performance.

Choosing the Right Size for Die-Cut Compostable Bags

Size selection is one of the most common sourcing challenges for fashion retailers.

Common Size Ranges Used in Fashion Retail

Typical sizes for die-cut compostable bags include:

- 300 × 400 mm – light apparel, accessories

- 350 × 450 mm – standard boutique takeaway

- 400 × 500 mm – bulkier garments or boxed items

Choosing a size that is too small creates packing difficulties, while oversizing increases material cost and reduces perceived quality.

Matching Bag Size to Retail Workflow

Before confirming size, buyers should consider:

- Average product dimensions

- Whether items are folded or boxed

- Whether multiple items are commonly packed together

These practical details help avoid unnecessary revisions during sampling.

Thickness and Strength Considerations

Film thickness directly affects both performance and printing results.

Typical Thickness Ranges

For fashion retail, die-cut compostable bags are commonly produced within the range of:

- 40–60 μm for light to medium apparel

- 60–80 μm for heavier garments or higher humidity conditions

Thicker films improve handle stability but also increase cost, so thickness should be specified based on actual use rather than assumption.

Handle Reinforcement and Stress Points

The die-cut handle area is the primary stress point during use. Reliable suppliers account for:

- Load distribution around the handle

- Tear resistance during repeated handling

- Consistent cutting quality

Ignoring these factors often leads to complaints during store-level use.

Printing on Die-Cut Compostable Bags

What Printing Works Best

Printing on compostable materials is feasible, but expectations should be realistic.

Best practices include:

- Simple logos or text-based branding

- Limited color palettes

- Adequate film thickness to support ink adhesion

Minimal designs often produce the cleanest and most consistent results at scale.

Common Printing Limitations

Some challenges to be aware of:

- Very fine details may lose sharpness

- Overly dense ink coverage can affect drying

- Handle areas are not suitable for critical design elements

Designing with the bag structure in mind helps avoid rework during production.

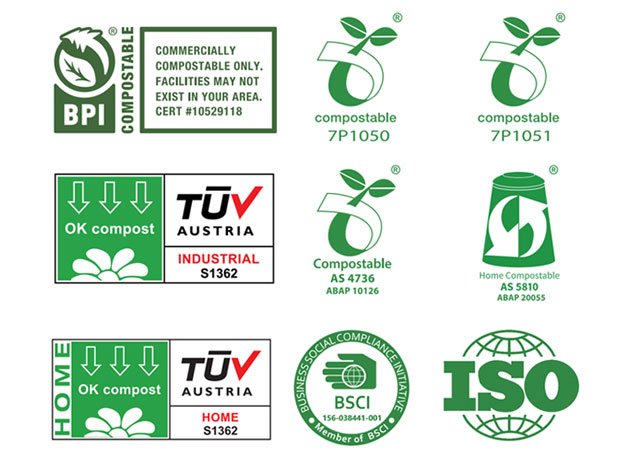

Compliance and Certification Requirements

For fashion retailers operating across different markets, compliance is not optional.

Common Certifications by Market

Depending on the destination market, die-cut compostable bags may need to comply with:

- EN 13432 – European Union (In the European market, compostable die-cut bags are typically required to meet EN 13432 standards, which apply to the finished bag rather than just the raw material. More details on testing scope and certification requirements can be found in our overview of EN 13432 certified compostable bags.)

- ASTM D6400 / BPI – United States

- AS 4736 / AS 5810 – Australia

Certification generally applies to the finished bag, not just the raw material.

Avoiding Greenwashing Risks

Using terms like “eco-friendly” or “biodegradable” without certification can create compliance and reputational risks, especially for fashion brands with public sustainability commitments.

Clear documentation and correct labeling are essential parts of responsible sourcing.

How to Source Die-Cut Compostable Bags for Fashion Retail

Key Specifications to Confirm Before Quoting

Before requesting quotations, B2B buyers should clearly define:

- Bag size and thickness

- Die-cut handle shape

- Printing requirements

- Target market certification

- Packing format

- Estimated order volume

- Delivery terms

Providing complete specifications reduces back-and-forth and speeds up sampling.

For buyers planning ongoing retail programs or private-label packaging, it is often more efficient to evaluate die-cut bags within a broader wholesale supply framework, including MOQ, batch consistency, and long-term lead time planning.

You can review general sourcing considerations for compostable shopping bags wholesale to better align specifications before requesting quotations.

What to Expect From a Capable Supplier

From a manufacturing standpoint, a qualified supplier should be able to support:

- Stable batch quality

- Consistent cutting and sealing

- Certification documentation

- OEM and private-label programs

- Long-term supply planning

These capabilities become increasingly important as retail programs scale.

Common Mistakes When Using Die-Cut Compostable Bags

Some issues appear frequently in fashion retail projects:

- Choosing size based on appearance alone

- Underestimating thickness requirements

- Placing key graphics near handle stress points

- Overlooking destination market compliance

- Treating compostable bags as a short-term solution rather than a repeat supply item

Addressing these points early helps ensure smoother rollouts.

Conclusion

Die-cut compostable bags offer a practical and visually clean solution for fashion retail packaging.

When size, thickness, printing, and certification are aligned with real retail needs, they can support both brand presentation and compliance requirements. For B2B buyers, approaching die-cut compostable bags as a structured sourcing decision—rather than a cosmetic packaging choice—leads to more consistent and predictable outcomes over time.