Have you heard of “biodegradable plastic bags”? What are they? Biodegradable bags are a new type of environmentally friendly garbage bag, available in many stores. What is the biodegradable plastic bags manufacturing process ? Why are they environmentally friendly?

As a manufacturer with 16 years of experience in biodegradable and compostable bag production, this article will take you through the entire process, from raw materials and production processes to market adoption, revealing the secrets behind biodegradable plastic bags.

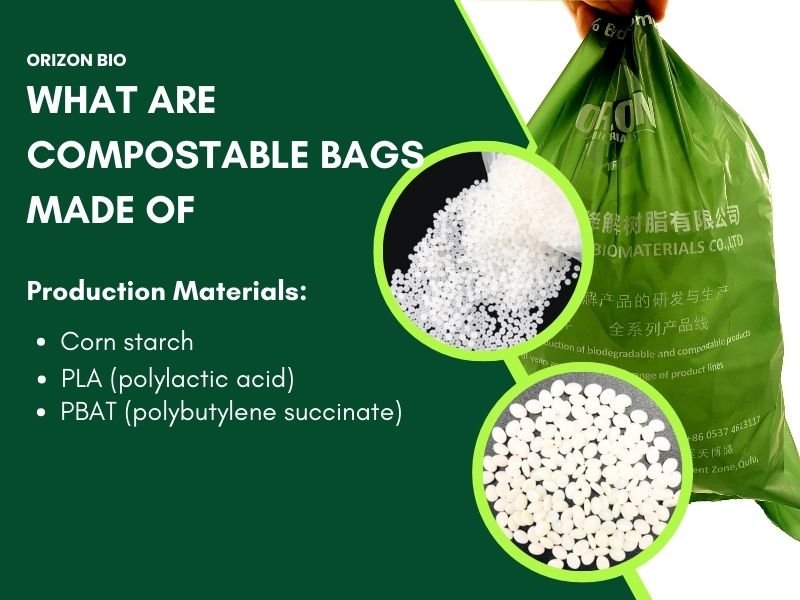

Raw Materials for Biodegradable Plastic Bags:

- PLA: Made from fermented corn starch, potato starch, and other materials, it’s inherently hard and brittle, naturally renewable, and relatively low-cost. It can be decomposed by microorganisms in natural environments, reducing environmental pollution.

- PBAT: The material is very soft and has excellent toughness, similar to plastic wrap. However, it’s significantly more expensive than PLA.

Common, cost-effective formulations:

By blending and modifying, the two are combined in a specific ratio (“70% PBAT + 30% PLA + an appropriate amount of filler masterbatch”), and adding other fillers (such as starch or calcium carbonate) to create a material with the perfect balance of performance and cost.

The flexibility of PBAT envelops the rigidity of PLA, resulting in bags with both sufficient strength and excellent stretchability, while also reducing costs! This is why some bags are soft and heat-resistant. Express delivery bags are more tear-resistant, while shopping bags are more environmentally friendly.

Related Artical : What Are Compostable Bags Made Of? 2025 Complete Guide

Biodegradable Plastic Bags Manufacturing Process

Material Pretreatment and Mixing:

A twin-screw extruder granulator mixes corn starch and polylactic acid in appropriate proportions. Sometimes, additives are added to enhance the bag’s toughness and ductility.

Extrusion Molding:

The mixed material is formed into a film through an extruder.

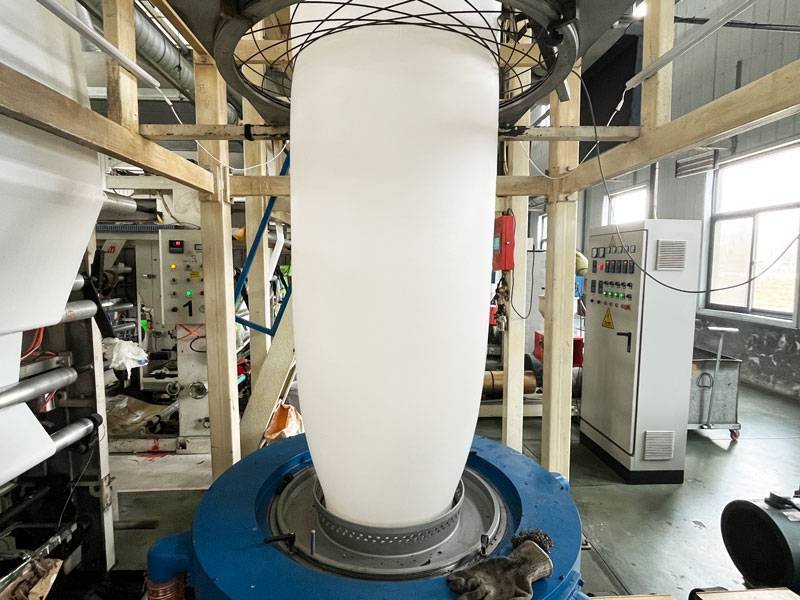

Film Blowing:

ABA three-layer co-extrusion blown film technology is used here to blow the film into a large tube, which is then formed into a flat plastic film, the bag blank we see.

ABA three-layer co-extrusion blown film technolog:

- Layer A (Outer Layer): Use a high-quality blend to ensure the bag’s appearance and printing quality.

- Layer B (Core/Filling): A higher filler content (such as calcium carbonate) can be added to significantly reduce costs without significantly affecting performance.

- Layer A (Inner Layer): Use a high-quality blend to ensure the bag’s strength and heat-sealability.

Key Factors Affecting Film Blowing:

- Temperature: The barrel and die temperatures must be strictly controlled between 150-180°C (adjusted based on the specific formulation). Too high a temperature will cause the material to decompose, while too low a temperature will result in poor plasticization.

- Cooling Air Ring: The blown “bubbles” need to be immediately cooled and fixed with air. The air volume directly affects the film’s transparency and thickness uniformity.

Bag Making Process:

- Printing: The blown film enters a copperplate gravure printer, currently using environmentally friendly water-based ink, to print the company logo or environmental protection logo on the bags.

- Bag Making: The printed film then enters a fully automatic heat-sealing and cold-cutting bag-making machine. The machine automatically heat-seals, cuts, and punches (to create handles for vest bags) according to the settings, creating bags of various sizes. Finally, the bags are neatly folded manually.

Quality Inspection:

After production, a series of tests, such as strength and degradability, are conducted to ensure that the products meet standards.

How Much Does a Biodegradable Bag Factory Cost?

1.Equipment Investment Cost:

Small Production Line: One small ABA film blowing machine + one bag making machine ≈ 300,000-500,000 RMB

Standard Production Line: Twin-screw pelletizer + medium-sized ABA film blowing machine + multi-color printer + fully automatic bag making machine ≈ 800,000-1.2 million RMB

High-end Production Line: The investment may be over 2 million RMB.

2.Cost and Profit Calculation

Let’s do a simple calculation (prices are examples only; please refer to local market prices):

- Raw Material Cost: Assume the mixed material cost is 20,000 RMB/ton.

- Other Costs: Electricity, labor, factory rent, packaging, etc., approximately 3,000 RMB/ton.

- Total Cost: Approximately 23,000 RMB/ton.

- Finished Product Selling Price: The market wholesale price is typically 26,000-30,000 RMB/ton.

- Gross Profit: Approximately 3,000-7,000 RMB/ton.

Conclusion: As long as there are stable orders and production costs are controlled, the profit margin is still considerable.

Minor Bugs During Manufacturing Process of Biodegradable Plastic Bags:

It’s normal to encounter problems during the production of biodegradable bags. Below are some pitfalls we’ve encountered in our factory, which we hope will be helpful.

1.What should I do if the blown film has “fish eyes” (small bumps)?

It’s 90% likely due to moisture in the raw materials! PLA absorbs water very easily. Before production, be sure to dry it in an 80°C oven for at least 4 hours. Check to see if the filter needs to be replaced.

2.The bag’s edge seal is weak and falls apart easily.

Increase the heat seal knife temperature or extend the heat seal time. Perhaps there’s a problem with the material ratio of the inner and outer layers, resulting in poor heat sealing.

3.Is the blown film thick on one side and thin on the other?

Check that the die’s discharge port is evenly spaced and adjust the air volume of the cooling air ring to ensure 360-degree uniform air flow.

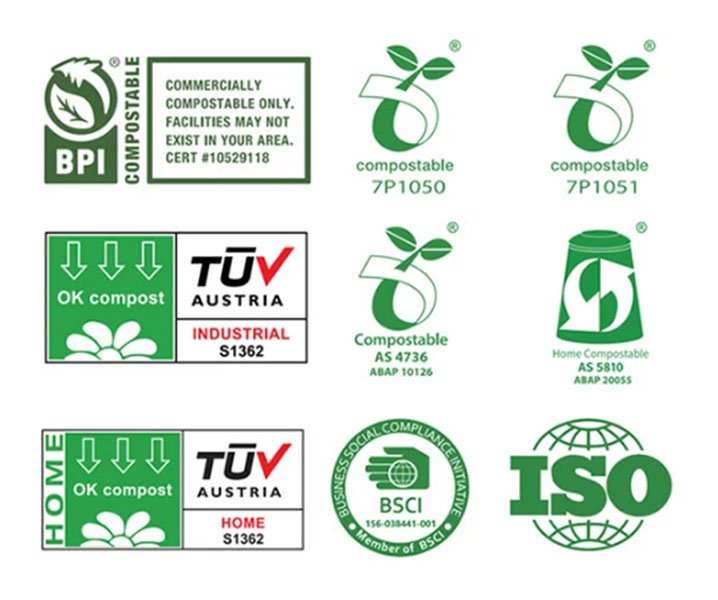

Certifications Required for Biodegradable Bags:

To expand your product into international markets, you need certification from a professional, authoritative organization.

- Chinese market: Look for the GB/T 38082 standard.

- EU market: EN 13432 certification (TUV Austria and DIN Certco) is required, which is the gold standard for industrial composting.

- US market: ASTM D6400 certification is required, along with the BPI certification mark (you can visit the BPI website to find the product identification code). This ensures that the product is fully degradable within 180 days and biodegradable within one year.

- Australia and New Zealand: AS 4736-2006 and AS 5810-2010, compost must be decomposed within six months and fully biodegraded within one year.

Application reminder: These certifications take a long time (usually 6-12 months) and are expensive.

FAQ

What makes biodegradable bags environmentally friendly?

The raw materials are biodegradable, and the production process minimizes energy and resource consumption. Some factories analyze carbon emissions and water consumption per kilogram of bag to ensure the overall environmental impact is minimized. Waste and exhaust gas generated during production are also recycled and treated to minimize secondary pollution.

What regulations and certifications do biodegradable bags need to comply with?

Biodegradable plastic bags are certified by international authorities such as BPI, ASTM, European EN standards, and industrial composting certification. Rigorous testing ensures that these bags can truly degrade in natural environments or industrial composting, without causing long-term environmental damage.

Conclusion

From raw material formulation to practical workshop operations, cost calculations, and market access, we’ve walked through the entire biodegradable plastic bag manufacturing process. Do you still find biodegradable bags mysterious?

The global “plastic ban” movement is sweeping the market, presenting both opportunities and challenges. But it always offers a welcome return to those who are prepared. We hope to help you choose truly biodegradable bags.

References:

- BPI: https://bpiworld.org

- TUV Austria : https://en.tuv.at/