As a business decision-maker or purchasing manager, you face increasing environmental pressure and market demand. Global plastic pollution is becoming increasingly severe, and consumers’ expectations for sustainable solutions are unprecedented. Compostable bags have become an ideal alternative to traditional plastic bags, not only helping to meet environmental compliance requirements but also significantly enhancing a brand’s sustainable image.

Faced with a wide variety of biodegradable materials on the market, such as PLA, PBAT, and PHA, how do we choose when purchasing? What are their differences? As a factory that has been producing biodegradable compostable bags for 16 years, this article will provide you with a comprehensive, practical, and in-depth guide to choosing compostable bag materials, hoping to help you understand the differences between these materials and make the right choice.

Compostable Bag Materials

Before delving into the specific materials, we need to understand some concepts, which are crucial for composting bags to truly appreciate their value.

If you have questions about the basic components of compostable bags, please read our article “What Are Compostable Bags Made Of?” first.

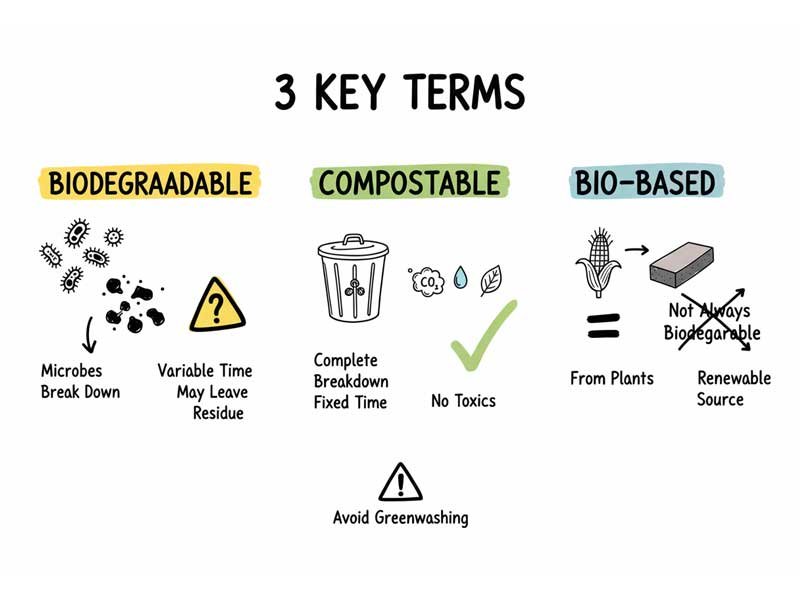

What is “biodegradable”?

Biodegradation: The process by which microorganisms (such as bacteria and fungi) break down materials into smaller molecules or elements. It has a broad scope, focusing on the decomposition products, the time required, and the environment in which the decomposition occurs.

Not all biodegradable materials completely decompose into harmless substances, nor do they all complete degradation in a short time; therefore, their environmental value varies.

What is “compostable”?

Compostable: This requires stricter standards. Under specific composting conditions, the material must completely decompose into carbon dioxide, water, inorganic salts, and biomass within a predetermined time (usually several weeks to several months), leaving no macroscopically visible or toxic residues.

Compostable bags, after industrial or household composting, can safely return to the natural cycle, becoming part of organic fertilizer. This is fundamentally different from materials that are only “biodegradable” but may leave microplastics or harmful residues.

What is “bio-based”?

“Bio-based”: The carbon content of the material derives at least part from renewable biomass (such as plants). For example, corn starch and sugarcane are common bio-based sources. It is important to note that bio-based materials are not necessarily biodegradable or compostable, and vice versa.

Understanding these technical terms is crucial to avoiding marketing “greenwashing” in the market.

Key Certifications and Standards: Ensuring Compostability

To ensure the true compostability of compostable bag materials, stringent certification standards have been established globally. These standards assess the material’s decomposition capacity, ecotoxicity, and heavy metal content through a series of tests.

| Category | Standard | Region | Description / Requirement |

|---|---|---|---|

| Industrial Composting Standards | EN 13432 | Europe | Must degrade ≥90% within 12 weeks under industrial composting conditions. Widely used across Europe. |

| ASTM D6400 | North America | Equivalent to EN 13432; sets requirements for plastics designed for industrial composting. | |

| AS 4736 | Australia | Australian industrial composting standard requiring biodegradation, disintegration, and ecotoxicity tests. | |

| Home Composting Standards | OK compost HOME | Europe | Requires materials to break down in low-temperature, variable home composting environments. |

| AS 5810 | Australia | Australian home composting standard ensuring products degrade safely in household compost systems. |

Comparison of Different Composting Bag Materials

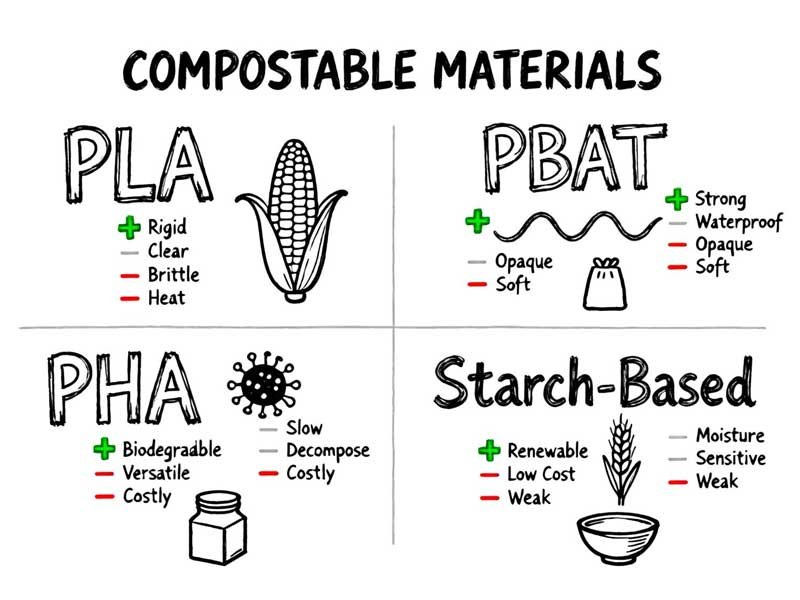

1.PLA — Polylactic Acid

1. Source & Production

- Made entirely from renewable biomass such as corn, cassava, and sugarcane.

- Fermented and polymerized to form a biobased plastic with a low carbon footprint.

2. Core Properties

Pros

- High transparency, glossy appearance

- Excellent rigidity and a crisp, premium hand-feel

- Easy to print on; great for branding

Cons

- Brittle and less flexible

- Limited heat resistance

- Sensitive to moisture during storage and use

3. Ideal Applications

- Transparent food packaging

- Produce liner bags

- Rigid containers

- Disposable cutlery

- Any packaging requiring clarity but low flexibility

PBAT — Polybutylene Adipate Terephthalate

1. Source & Production

- Can be partially bio-based or petroleum-based.

- Bio-based PBAT usage is increasing in the market.

2. Core Properties

Pros

- Outstanding flexibility and toughness

- High puncture and tear resistance

- Excellent water resistance

- Fast degradation rate

- Suitable for film blowing

Cons

- Low transparency (usually milky or semi-transparent)

- Soft texture, less structured than PLA

3. Ideal Applications

- Food waste bags

- Shopping bags

- Mailer bags

- Agricultural mulch film

- Products requiring strong flexibility

PHA — Polyhydroxyalkanoates

1. Source & Production

- 100% bio-based, produced by microbial fermentation.

- One of the most environmentally friendly compostable polymers.

2. Core Properties

Pros

- Fully biodegradable in industrial, home, soil, and marine environments

- Excellent biocompatibility

- Good balance between strength and flexibility

Cons

- High production cost

- Limited global availability

- Narrow processing window

3. Ideal Applications

- High-end packaging

- Medical and hygiene products

- Premium disposable cutlery

- Applications requiring extreme environmental degradability

Starch Blends

1. Source & Production

- Blend of natural starch (corn, cassava, etc.) with PLA or PBAT.

- High biobased content and customizable performance.

2. Core Properties

Pros

- High renewable content

- Cost-effective

- Easy to process

Cons

- Lower mechanical stability

- Sensitive to humidity

- Poor transparency

3. Ideal Applications

- Low-cost disposable bags

- Packaging filler materials

- Short-term use products with low strength requirements

How to Choose the Right one Compostable Bag Materials

| Property | PLA (Polylactic Acid) | PBAT (Polybutylene Adipate Terephthalate) | PHA (Polyhydroxyalkanoates) | Starch Blends |

|---|---|---|---|---|

| Bio-based Content | High (renewable plants) | Low to medium (petroleum-based or partially bio-based) | High (microbial fermentation) | High (renewable plants) |

| Flexibility | Poor (brittle) | Excellent (very flexible) | Good | Medium (affected by moisture) |

| Tensile Strength | High | Medium | Good | Medium |

| Puncture Resistance | Poor | Excellent | Good | Medium |

| Heat Resistance | Low (about 50–60°C) | Good (about 90–110°C) | Good | Low |

| Transparency | High (crystal clear) | Low (milky/semi-transparent) | Medium | Low |

| Water Resistance | Poor (hydrolysis-sensitive) | Excellent | Good | Poor (high moisture absorption) |

| Degradation Conditions | Industrial composting | Industrial composting (some grades home compostable) | Industrial & home composting, soil & marine degradation | Industrial & home composting |

| Degradation Speed | Medium | Fast | Fast | Fast |

| Printability | Excellent | Good | Good | Medium |

| Relative Cost | Medium | Medium | High | Low to medium |

| Processing Difficulty | Medium (requires precise temperature control) | Low | High (narrow processing window) | Medium (may stick during processing) |

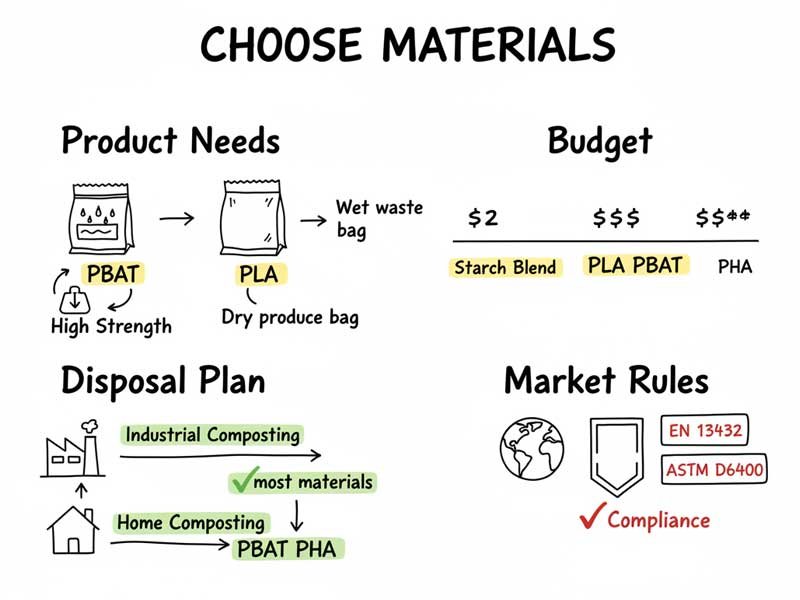

How to Choose Materials Based on Business Needs

- Assess Your Product Characteristics:

Contents: What will your bags be used to package? For moist kitchen waste, PBAT’s water resistance and flexibility are ideal; for dry, display-ready produce, PLA’s transparency and rigidity are more advantageous.

Weight and Size: If load-bearing or puncture-proof properties are required, high-strength materials such as PBAT or PHA are preferred.

Storage Requirements: If specific oxygen or moisture barrier requirements are needed, further consideration of the material’s barrier properties or a multi-layered composite structure is necessary.

- Consider Your Budget:

PLA and PBAT are generally within an acceptable cost range, while PHA is more expensive due to its superior degradation properties and lower production costs. Starch-based blends may offer a more cost-effective option.

- Define Your Disposal Plan:

How will your final waste be disposed of? If your target market has well-developed industrial composting infrastructure, most certified compostable materials are suitable. If consumers prefer home composting, materials certified for home composting (such as some PBAT or PHA) should be chosen. Understanding this is crucial to ensuring compostable bags truly deliver their environmental value.

- Target Markets and Regulatory Requirements:

Different countries and regions have different regulations and incentive policies regarding compostable packaging materials. Understanding and complying with the relevant standards of the target market (such as EN 13432 in the EU or ASTM D6400 in North America) is fundamental to compliance.

How B2B Companies Make Procurement Decisions

Choosing the right material for compostable bags is not just a matter of “technical parameters,” but a synergistic result of a comprehensive procurement strategy and supply chain management.

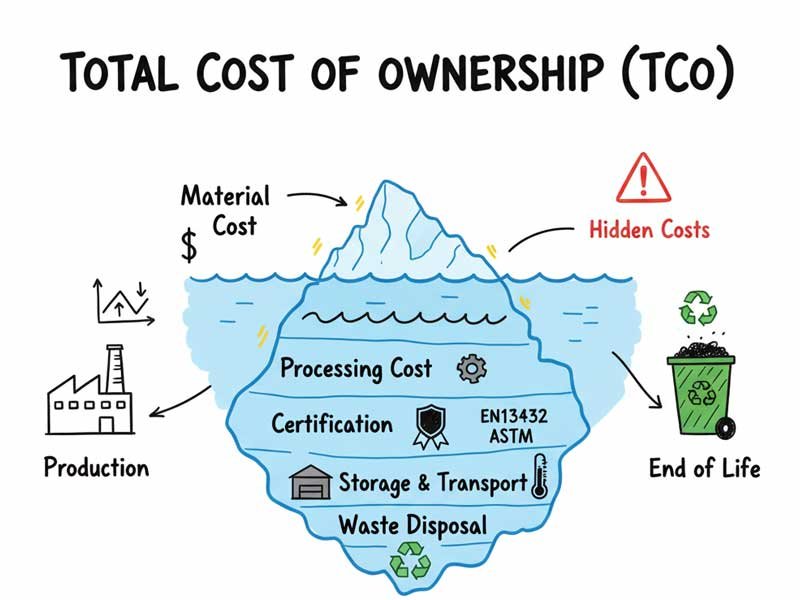

1.How to assess costs: Don’t just focus on raw material prices

Many procurement professionals only look at the “unit price of materials,” but this is only the tip of the iceberg. What you really need to calculate is the “Total Cost of Ownership” (TCO).

You need to pay attention to:

- Material Costs

Pay close attention to hidden variables such as market price fluctuations, bulk purchase discounts, and transportation costs.

- Processing Costs

Different materials vary greatly in their “processability.” For example, some materials are easy to blown into film, while others are very sensitive to temperature control; even a slight deviation can waste a batch of material.

- Certification Costs

If your product requires certifications such as EN13432, ASTM D6400, AS 4736, and AS 5810, there are also costs involved. However, certification is the “ticket” to enter the market; you can’t do without it.

- Storage and Transportation Costs

Compostable materials are relatively delicate, sensitive to temperature and humidity. Improper storage leading to spoilage incurs additional costs.

- Waste Disposal Costs

In some countries, compostable bags entering the composting system can reduce waste disposal fees. This is also part of the cost.

2.How to Choose a Supplier: Reliability is More Important Than Cheapest

Finding a supplier is like finding a partner; reliability is more important than price.

- Qualifications and Certifications

Suppliers must provide genuine and valid compostable certifications (such as TÜV Austria, BPI) and ISO quality system certifications.

- Sample Testing

Testing is mandatory before bulk production, including:

- Tensile, tear, and puncture strength

- Heat resistance

- Transparency

- Printing effect

- Compostability

- Production Capacity & Quality Control

You need to confirm the supplier’s stable production capacity, high yield rate, mature technology, and traceable quality.

- Customization Capability

Your bags may require special specifications, colors, custom printing, or specific functions; the supplier must be able to meet these requirements.

- Supply Chain and Technical Support

Stable supply is essential, and timely assistance is crucial to resolve any processing issues.

3.Storage and shelf life:

Compostable materials are “active materials,” and improper storage will cause them to degrade prematurely.

- Optimal Storage Method

- Cool, dry, and well-ventilated area

- Avoid direct sunlight and high temperatures

- Preferably below 25°C

- Humidity around 50–60%

- Shelf Life Differences Between Different Materials

- PLA: Most susceptible to moisture, high risk of hydrolysis

- PBAT: Relatively stable

- Starch-based: Sensitive to moisture, easily softens

- Risks of Improper Storage

- Brittleness

- Adhesion

- Decrease in strength

- Difficulty in processing

4.Why Use Hybrid Materials:

- PLA + PBAT

- The most common and proven combination:

- PBAT provides flexibility and tear resistance.

- PLA provides rigidity and bio-based content.

- Suitable for shopping bags, courier bags, garbage bags, etc.

It can be described as a “golden combination of performance and cost.”

- Starch + PBAT / PLA

Advantages:

- Increases bio-based content.

- Reduced cost.

Disadvantages:

- Decreased strength.

- Poorer water resistance.

- Suitable for applications that do not require high performance.

- Customized Formulations

Good material suppliers can tailor formulations to your product needs, such as:

- Improved heat resistance.

- Increased flexibility.

- Optimized strength.

- Improved processability.

This is ideal for B2B customers who need differentiated products.

Industry Case Studies and Future Trends

Many leading brands have successfully integrated compostable bag materials into their businesses. Large supermarket chains such as Walmart and Metro have fully adopted PBAT or PLA/PBAT blends for their food waste bags and shopping bags, effectively reducing plastic waste.

Fashion brands and e-commerce platforms have also begun using PLA or PBAT-based compostable delivery bags to enhance their sustainable supply chain image. These examples demonstrate that adopting the right compostable bag material is not only an environmental responsibility but also a key to improving market competitiveness.

Future Development of Compostable Materials:

The compostable bag material sector is experiencing rapid growth.

- Research and Development of Novel Bio-based Materials: Scientists are exploring more innovative bio-based materials, such as algae-based polymers and cellulose-based materials, to further reduce dependence on traditional petroleum.

- Further Reduction in Production Costs: With large-scale production and technological advancements, we expect the production cost of compostable bag materials to continue to decline, making them more competitive in the market.

- Improved Degradation Efficiency and Broader Environmental Adaptability: Future materials will focus on achieving efficient degradation under a wider range of environmental conditions (such as room temperature, soil, and seawater) while maintaining excellent performance.

- Improved Regulatory and Standard Systems: With increasing global attention to environmentally friendly packaging, relevant regulations and certification systems will continue to improve, providing clearer guidance for businesses.

Conclusion

Choosing the right compostable bag material is a crucial step for businesses towards sustainable development. This requires not only a deep understanding of the characteristics, costs, and degradation mechanisms of different materials, but also a systematic procurement strategy and supply chain management approach.

Through this article, we hope you have gained a comprehensive understanding of compostable bag materials such as PLA, PBAT, PHA, and starch-based blends, and have learned how to make the best choice based on your business needs. Actively embracing compostable packaging solutions is not only fulfilling corporate social responsibility, but also a wise move to adapt to market trends and enhance brand value.

If you still have questions about choosing compostable bag materials, or require customized solutions, please feel free to contact our expert team. We will provide you with professional consulting services and work together to explore the most suitable green packaging path for you.