When I speak with packaging buyers, many of them tell me the same thing: “whether they can meet the performance and sourcing requirements of their current packaging.”

I understand this confusion. The term “home compostable” is frequently used, but its meaning varies depending on the market, customer base, and materials chosen. In this guide, I will explain what home compostable bags are, how they perform, and what you should know before sourcing them for your brand.

What “Home Compostable” Really Means for Businesses

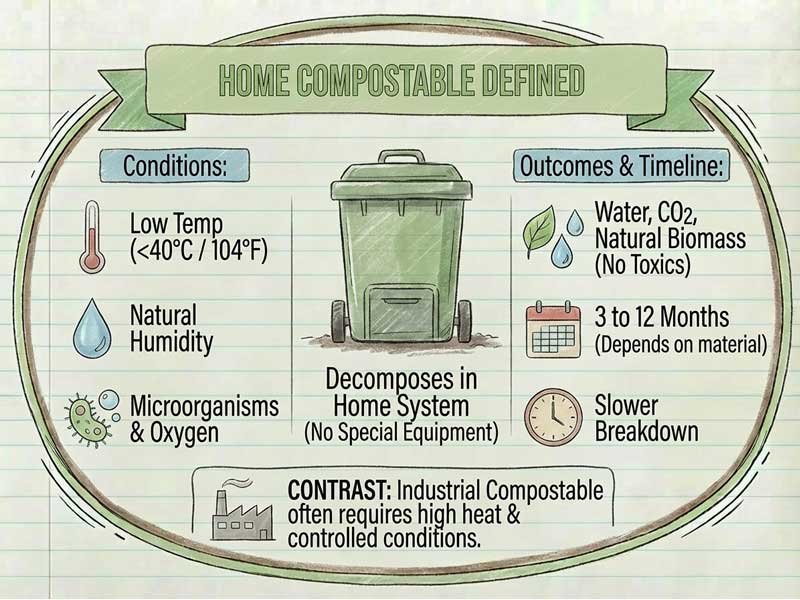

“Home compostable” means that these bags decompose in a home composting system under normal conditions, without the need for special heating or industrial equipment.

Unlike industrial compostable bags, these materials must decompose at a lower temperature—typically below 40°C.

To qualify as home compostable, the bag must:

- break down within a set time under home compost conditions

- release no harmful substances

- which ensures the material does not leave harmful residues in soil.

Standards like AS5810 and OK Compost HOME define these rules. When someone tells me a bag is “compostable,” I always ask: Is it for home composting or industrial composting?

Because the answer is crucial, as these two types of composting processes are fundamentally different.

Home Compostable Standards and Certifications You Should Know

For B2B packaging, certification is not optional; it protects your brand from misleading advertising and ensures customers aren’t misled.

AS5810 (Australia)

AS5810 is one of the most stringent home composting standards. It tests the packaging under low-temperature, real-world home composting conditions. The product must decompose completely without producing any ecotoxicity.

For more information on the AS5810 requirements, you can refer to our detailed guide::Australian AS5810 Home Compostable Standard: The Ultimate Guide

OK Compost HOME (Europe)

This certification verifies that the packaging can decompose in a home environment. Many European retailers require this label on all home compostable packaging.

Why Industrial Standards Aren’t Enough

Certifications like EN13432, BPI, and AS4736 are industrial composting standards. They assume conditions of high temperature, controlled humidity, and large composting facilities.

Even if a product passes industrial testing, it may not decompose at home. I’ve seen buyers make this mistake, and it often leads to customer complaints.

Home Compostable Plastic Materials Used in Bags

Material choice affects strength, shelf life, sealing performance, and composting speed. When I compare suppliers, I usually look at the base materials first. Not all compostable materials behave the same way, and some are better suited for bags.

Here are the most common options:

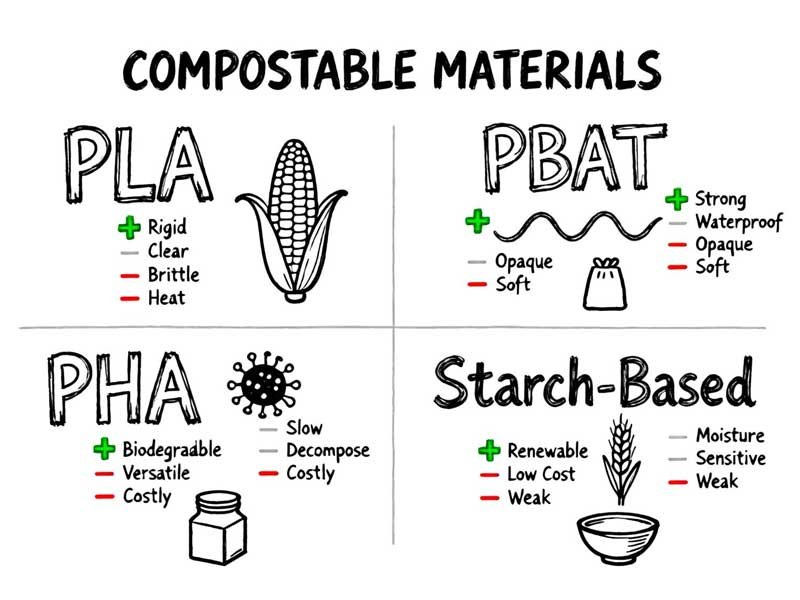

PHA (Polyhydroxyalkanoates)

PHA is known for breaking down at low temperatures. Because microbes naturally digest PHA, it performs well in real home compost.

It can be more expensive but works well for retail bags, produce bags, and mailer films.

PLA + PBAT Blends

PLA (polylactic acid) is made from corn or sugarcane. PLA alone is not home compostable, but when blended with PBAT (a biodegradable polymer), it can break down more easily.

These blends are common in mailer bags and thicker carry bags.

PBS or Starch-Based Materials

These materials have good flexibility and feel close to LDPE. Some versions pass home compost tests; others do not.

I always check the certification rather than trusting material names.

Cellulose Films

These films come from plant fibers. They are clear and crisp—good for windows or lightweight bags. But the strength is limited compared with PHA or PLA blends.

Types of Home Compostable Bags

Packaging buyers often want to know which bag types actually work with home compostable films. Here are the main categories.

Retail Shopping Bags

These usually use PLA blends or PBS-based films. They work well for supermarkets and fashion stores.

Produce & Roll Bags

Common in supermarkets for fruit and vegetables.

PHA-based films handle moisture better, which helps with fresh produce.

Home Compostable Mailer Bags

Many e-commerce brands now adopt compostable mailers. They look and feel like soft plastic but come from renewable materials.

Performance depends on thickness and film blend.

Compostable Garment & Inner Packaging Bags

Many fashion brands now replace clear PE garment bags with home compostable versions.

These Compostable Garment bags protect clothing from dust and moisture during transport but still break down under home compost conditions.

Film clarity and softness vary depending on the base material.

Compostable Garbage Bags

Used in households, hotels, offices, and food-service settings.

These bags typically use flexible home compostable films that can handle wet organic waste.

They are designed to break down without leaving toxic residue and fit standard bin sizes.

However, their strength still depends on film thickness and material blend.

Dog Waste Bags

Dog poop bags are one of the most common home compostable applications.

They must balance durability with ease of breakdown in backyard compost systems.

Brands often choose darker or opaque films for better appearance while maintaining compostability.

Nappy / Diaper Disposal Bags

These small nappy bags help parents dispose of baby diapers more responsibly.

They are designed for single use and must seal odors effectively while remaining home compostable.

Strength and leak resistance are key considerations for B2B buyers

Home Compostable Bags vs Traditional Plastic Bags

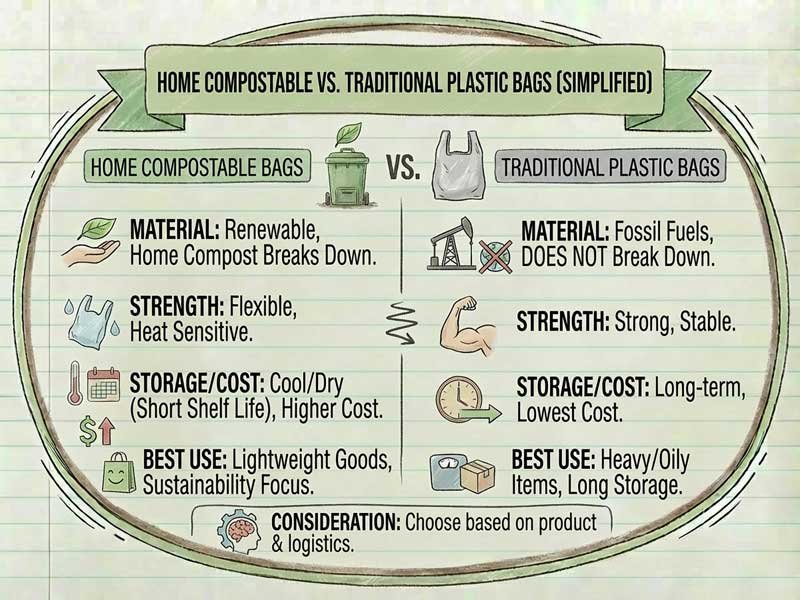

Many buyers ask me whether home compostable bags can truly replace traditional plastic bags. The short answer is: sometimes, but not in every situation.

Here is a clear, simple comparison to help you evaluate both options.

Material & End-of-Life

Home compostable bags are made from renewable materials like PHA, PLA/PBAT blends, or starch-based films. They break down in a home compost environment when conditions are right.

Traditional plastic bags (such as PE) come from fossil fuels and do not break down naturally. If they are not recycled, they stay in the environment for many years.

Strength & Durability

Home compostable films have good flexibility, but they are generally less tear-resistant than PE. They can also be affected by heat and humidity.

Traditional plastic bags are strong even at low thickness and remain stable in almost any storage condition.

Storage & Logistics

Compostable bags need cool, dry storage and usually have a shelf life of 6–12 months.

Plastic bags can be stored for years without changes, making them easier for long supply chains.

Cost

Home compostable bags cost more because of renewable materials and limited production capacity.

Traditional plastic bags remain the lowest-cost option.

When Each Material Works Best

- Home compostable bags work well for lightweight items, produce, retail packaging, and brands with sustainability goals.

- Traditional plastic bags are still better for heavy products, oily foods, or long-term storage.

If you are choosing between the two, I always recommend thinking about your product type, customer expectations, and how the bags will be stored and transported.

Performance Considerations for Brands

When I advise packaging teams, we often discuss performance before anything else.

Shelf Life and Storage

Home compostable bags usually have a shorter shelf life than traditional plastic. High heat or humidity can speed up aging.

Most suppliers recommend storing bags at 20–30°C, away from sunlight.

Strength and Thickness

These bags can replace LDPE bags in many uses, but not always for heavy loads.

Mailer bags typically range from 50–80 microns, while shopping bags generally require 40–60 microns..

Heat and Moisture Sensitivity

Humidity affects compostable materials faster than PE or PP.

If your supply chain includes long sea freight or warehouse storage, you should test the film in your own environment.

Limitations of Home Compostable Bags

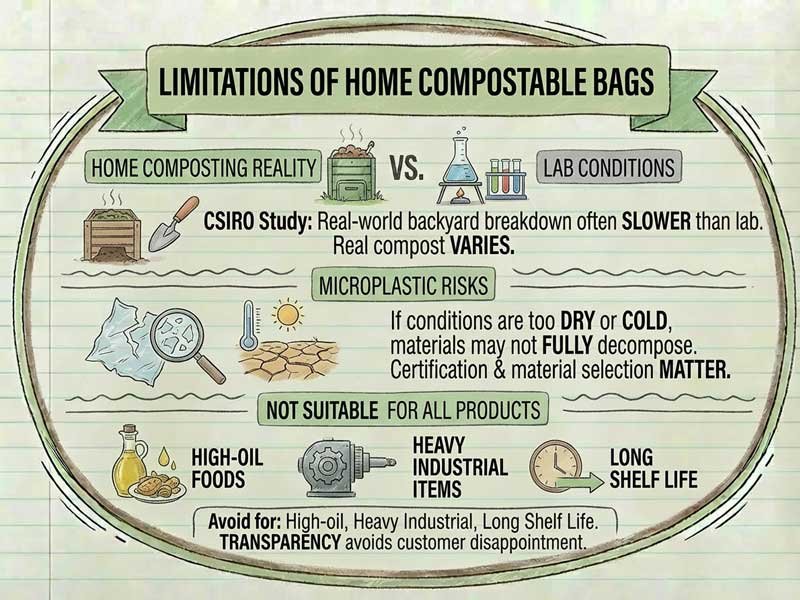

Home Composting Reality vs Lab Conditions

A study from CSIRO found that many home compostable plastics break down more slowly in real backyards than in lab environments(source: CSIRO, Australia).

This doesn’t mean the standards are wrong—it means real compost varies a lot.

Microplastic Risks

If conditions are too dry or too cold, some materials may not fully decompose.

This is why certification and proper material selection matter.

Not Suitable for All Products

For some products, these limitations make traditional plastic a safer option, I usually advise against using home compostable bags for:

- high-oil foods

- heavy industrial items

- goods requiring long shelf life

Transparency helps your brand avoid customer disappointment.

Regulatory Considerations in AU, EU, and US Markets

Different markets have different rules for compostable packaging.

Australia

Many retailers expect AS5810 for home compostable claims.

Some councils do not accept compostable bags in green bins.

European Union

Clear rules prevent vague claims like “biodegradable.”

Only certified home compostable bags can display home compostable logos.

United States

There is no national home composting standard, so buyers depend on certifications like OK Compost HOME.

How Brands Should Communicate “Home Compostable” Correctly

When I help brands review packaging claims, the same issues come up repeatedly.

Approved Claims

- “Certified home compostable according to AS5810 / OK Compost HOME.”

- “Breaks down in a home compost environment.”

Claims to Avoid

- “Fully biodegradable in any environment.”

- “Breaks down everywhere.”

- “Eco-plastic.”

Clear Disposal Instructions

Buyers can add simple guidance such as:

“Place in a home compost bin. Not suitable for recycling.”

How to Choose a Home Compostable Bag Supplier

These items help you compare suppliers more clearly and reduce the risk of product failure in real use.

Vendor Checklist

- Valid home compostable certifications

- Material data sheets

- Printing options

- Thickness ranges

- QC process for each batch

- Lead time and MOQ

Questions to Ask

- What material blend is used?

- How long is the bag’s shelf life?

- Can you provide real compost test results?

- What are the ideal storage conditions?

A reliable supplier should answer these questions without hesitation.

FAQs

Do home compostable bags replace plastic bags?

Sometimes. It depends on weight, moisture, and barrier needs.

How long do they last in storage?

Most last 6–12 months if kept cool and dry.

Can I export compostable bags globally?

Yes, but you must check local labeling laws.

Conclusion

Home compostable bags can be a strong option for brands aiming to reduce plastic use, but they also require careful planning. Material choice, certification, storage, and supplier capability all play important roles in how well these bags perform. With the right information, you can choose packaging that supports your sustainability goals without compromising product quality.