Sustainable clothing packaging has become a critical decision point for apparel brands, not just a sustainability talking point. As regulations tighten and consumers demand transparency, packaging choices now directly affect compliance risk, brand trust, and long-term costs.

For fashion brands, the challenge is no longer whether to switch to sustainable packaging—but which materials actually work, how much they cost in real-world use, and how to stay compliant across different markets.

This guide is written specifically for apparel brands, sourcing teams, and sustainability managers who need practical answers—not marketing slogans.

Drawing on over 16 years of manufacturing experience in compostable packaging, we break down the most common sustainable clothing packaging options, compare recyclable and compostable materials, explain certification requirements (such as EN 13432 and ASTM D6400), and share what brands should realistically expect in terms of performance and cost.

Whether you are evaluating compostable garment bags for the first time or reassessing your current apparel packaging strategy, this page will help you avoid greenwashing risks and make informed, compliant decisions.

What Is Sustainable Clothing Packaging?

Sustainable clothing packaging refers to packaging solutions designed to minimize environmental impact throughout their entire lifecycle—from material sourcing and production to transportation, use, and end-of-life disposal.

Unlike traditional plastic packaging, which can persist in landfills and oceans for hundreds of years, sustainable apparel packaging aims to reduce waste, lower carbon footprint, and support circular economy models.

In practice, sustainable clothing packaging typically falls into three categories:

- Recyclable packaging (paper, cardboard, rPET)

- Biodegradable packaging (with varying and often unclear degradation outcomes)

- Certified compostable garment bags (tested under standards such as EN 13432 / ASTM D6400)

Each option has different implications for cost, performance, and compliance—making material selection a strategic decision rather than a cosmetic one.

Sustainable Clothing Packaging Materials: Recyclable vs Compostable

Fashion brands generally consider three main categories of sustainable packaging materials.

Recyclable Materials

Recycled paper, cardboard, and rPET are widely used and familiar to consumers. They work well when recycling infrastructure is reliable, but contamination and sorting limitations still exist in many regions.

Biodegradable Materials

Some materials break down over time, but “biodegradable” is a broad and often unregulated term. Inconsistent degradation and the risk of microplastic residue make this category difficult to control.

Compostable Materials (A Closed-Loop Solution)

Certified compostable packaging goes a step further. Under defined composting conditions, these materials fully decompose into water, carbon dioxide, and organic matter—without leaving harmful residues. This is why many brands are paying closer attention to compostable garment bags.

Before you decide on materials, start with the basics: garment bag size and thickness. The right specifications reduce shipping damage, wasted material, and customer complaints.

Why Fashion Brands Are Switching to Compostable Garment Bag

From my experience working with fashion brands, the shift toward compostable clothing packaging is driven by several practical factors.

Consumer Expectations Are Changing

Shoppers increasingly evaluate brands based on their environmental behavior, not just product design. Packaging is often the first physical interaction a customer has with a brand—and plastic waste leaves a strong negative impression.

Differentiation in a Competitive Market

Packaging has become a “silent communicator.” A soft, transparent compostable garment bag feels very different from thin plastic. Brands use this detail to reinforce a premium or responsible image without changing the product itself.

Regulatory and Compliance Pressure

Many regions are tightening restrictions on single-use plastics. Brands selling across borders must consider compliance in advance. Certified compostable packaging helps reduce regulatory uncertainty.

For brands selling across different regions, understanding compostable certification standards is critical. The requirements and expectations can vary significantly between Europe and the United States.

To avoid compliance risks and misleading claims, we explain the key differences in EN 13432 vs ASTM D6400 and how each certification applies to compostable packaging.

Long-Term Cost Stability

While compostable materials may appear more expensive at first glance, they can reduce long-term risk related to plastic taxes, penalties, and forced packaging changes.

Compostable Garment Bags: Materials and Performance

Most compostable garment bags used in apparel packaging are made from blends of PLA (polylactic acid) and PBAT.

- PLA is derived from renewable plant sources such as corn starch. It provides structure and clarity.

- PBAT adds flexibility and tear resistance, making the bags suitable for transport and retail handling.

In real applications, properly manufactured compostable garment bags are strong, flexible, and protective. They are not fragile novelty items—a misconception I still hear surprisingly often.

Certifications That Matter for Compostable Apparel Packaging

One of the most important lessons I share with brands is this:

certification matters more than claims.

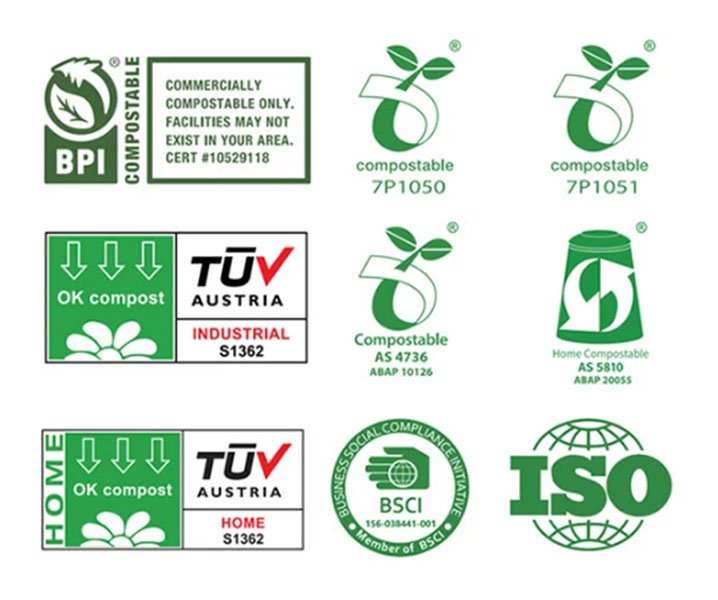

Reputable compostable garment bags should meet recognized standards such as:

- EN 13432 (Europe)

- ASTM D6400 / BPI (North America)

- OK Compost (Industrial or Home)

These certifications require third-party testing for biodegradability, disintegration, and toxicity. Logos without verifiable certificate numbers should always be treated with caution.

Cost vs Performance: What Brands Should Expect

Sustainable packaging decisions often start with cost concerns. That’s understandable.

However, when brands evaluate packaging holistically—performance, compliance, brand perception, and long-term risk—the conversation usually changes. Compostable garment bags today can meet the same functional requirements as plastic in most apparel use cases, including protection against dust, moisture, and handling damage.

The key is matching material specifications to real usage conditions rather than assuming all eco-friendly packaging behaves the same.

Challenges When Switching to Sustainable Apparel Packaging

The transition is not without challenges:

- Higher perceived material costs

- Uncertainty about strength or durability

- Difficulty identifying reliable suppliers

- Consumer confusion around disposal

These challenges are real, but they are manageable with the right planning and supplier transparency.

How to Choose a Sustainable Packaging Supplier for Fashion Brands

When evaluating suppliers, brands should focus on fundamentals rather than marketing promises.

Key questions to ask:

- Are certification numbers verifiable on official databases?

- Can the supplier clearly explain material composition?

- Are test reports and production standards available?

- Is there experience supplying regulated markets?

From a manufacturer’s perspective, transparency and consistency are the strongest indicators of reliability.

Compostable vs Biodegradable Packaging: What Buyers Need to Know

“Biodegradable” and “compostable” are often used interchangeably, but they are not the same.

Compostable packaging follows strict standards and fully breaks down into safe byproducts within a defined timeframe. Biodegradable packaging may degrade slowly or incompletely, sometimes leaving residues behind.

For fashion brands making sustainability claims, this distinction is critical.

The Challenges We Face

Making change is never without challenges. I understand the concerns brands may have when switching to sustainable packaging.

We are facing unprecedented environmental challenges. Every year, hundreds of millions of plastic packages are produced, used, and ultimately discarded, floating in the oceans and accumulating in landfills, taking hundreds of years to decompose and causing devastating damage to ecosystems. A report by the United Nations Environment Programme (UNEP) shows that approximately 400 million tons of plastic waste are generated globally each year, with a recycling rate of less than 10%.¹ This environmental impact is forcing major brands to rethink their operating models.

Against this backdrop, consumers, especially younger generations (Generation Z and Millennials), are showing unprecedented concern for environmental issues. They are no longer satisfied with just the appearance and function of fashion products, but are paying more attention to the production processes behind them and the impact on sustainable textiles and packaging. A McKinsey and BoF report, “The State of Fashion,” shows that over 70% of consumers are willing to pay higher prices for sustainable products. Their expectations of brands have also shifted from “providing products” to “taking social responsibility.”

Meanwhile, the phenomenon of “greenwashing” has also raised concerns among consumers. Brands that only make verbal promises without taking concrete environmental actions are facing a growing crisis of trust. Consumers are shifting their mindset, craving truly transparent environmental practices. This is forcing brands to invest real money and make tangible changes to make waste reduction a consensus.

Common Challenges

- Cost Considerations: Eco-friendly materials are sometimes more expensive than traditional materials. That’s a fact.

- Performance Concerns: Some people worry that eco-friendly materials are not as strong and durable as traditional materials.

- Supply Chain Complexity: Finding reliable, truly eco-friendly suppliers can take time.

Our Solutions

I always tell my clients to think long-term.

- ROI: The initial cost may be a little higher, but think about the enhanced brand image, increased customer loyalty, and future regulatory compliance. These are huge, intangible returns.

- Quality Assurance: Our compostable clothing bags undergo rigorous international standard testing to ensure they provide sufficient protection to meet your shipping and retail needs while being eco-friendly. They are not fragile.

- Simplified Supply Chain: This is where Orizonbags comes in. We focus on the research and development and production of compostable clothing bags. This means you don’t need to search around; we can provide you with a stable, high-quality solution. We have an excellent understanding of materials, production, and certification.

Brand Checklist: Choosing Sustainable Clothing Packaging

Before making a final decision, brands should review:

- Target market regulations and labeling requirements

- Available disposal infrastructure (recycling vs composting)

- Packaging performance needs during shipping and storage

- Supplier certifications and material transparency

- Alignment with brand sustainability messaging

This approach helps avoid greenwashing risks while ensuring practical results.

The Future of Sustainable Fashion Packaging

Compostable garment bags are just the start. Here’s what brands can expect next:

- Better Materials

Scientists are developing even smarter options: water-soluble bags for delicate fabrics, mushroom-based packaging for luxury brands, and agricultural waste blends that cut costs.

- Circular Models

Brands will move beyond one-time use. Expect “returnable packaging” programs (shoppers send back bags for reuse) and modular designs (bags that split into smaller pouches).

- More Infrastructure

By 2030, most cities in Europe and North America will have industrial compost facilities. This makes industrial compostable clothing packaging as convenient as recycling.

- Custom Collaboration

Brands and suppliers will work closer to create unique solutions—like bags with NFC tags (shoppers scan to see your eco-journey).

FAQ

How brands are using compostable garment bags?

Many brands use compostable garment bags as inner packaging to protect apparel while reducing plastic waste and supporting sustainability commitments.

Are compostable garment bags really compostable?

Yes—when certified under standards such as EN 13432 or ASTM D6400 and disposed of in appropriate composting environments.

Are all compostable bags suitable for home composting?

No. Some are designed only for industrial composting. Home compostable certification should be checked carefully.

Compostable vs biodegradable packaging for apparel: what’s the difference?

Biodegradable packaging may break down slowly and inconsistently, sometimes leaving residues. Compostable packaging follows strict standards, ensuring complete breakdown into non-toxic materials within a specified period under controlled composting conditions.

How to choose a supplier for sustainable apparel packaging?

Choose suppliers that provide verifiable certification numbers, clear material composition details, recent test reports, and proven experience supplying regulated markets. Transparency and compliance are more important than marketing claims.

Conclusion

Sustainable clothing packaging is no longer a future concept—it is already shaping how fashion brands operate, communicate, and compete.

From my experience, brands that succeed are those that treat packaging as part of their product responsibility, not an afterthought. Whether choosing recyclable solutions or certified compostable garment bags, the goal is the same: reduce environmental impact without compromising performance or credibility.

Thoughtful packaging choices may seem like small details, but over time, they define how a brand is perceived—by customers, partners, and regulators alike.

P.S. We offer custom printing (12 colors, logos, or brand messages) and combo deals—pair compostable bags with sustainable shipping labels for extra savings. Just ask our team!

Sources:

- https://www.unep.org/zh-hans/news-and-stories/press-release/quan-qiu-yi-ci-xing-su-liao-cha-xun-zhi-nan

- EU Single-Use Plastics Directive: Directive (EU) 2019/904 eur-lex.europa.eu

- California Plastic Bag Ban + Fines : California SB 270 & AB 793 calrecycle.ca.gov

- ASTM D6400: American Society for Testing and Materials, astm.org

- EN 13432 : European Committee for Standardization – cen.eu

- BPI Certification : Biodegradable Products Institute – bpiworld.org